get to know us

ODM vs OEM

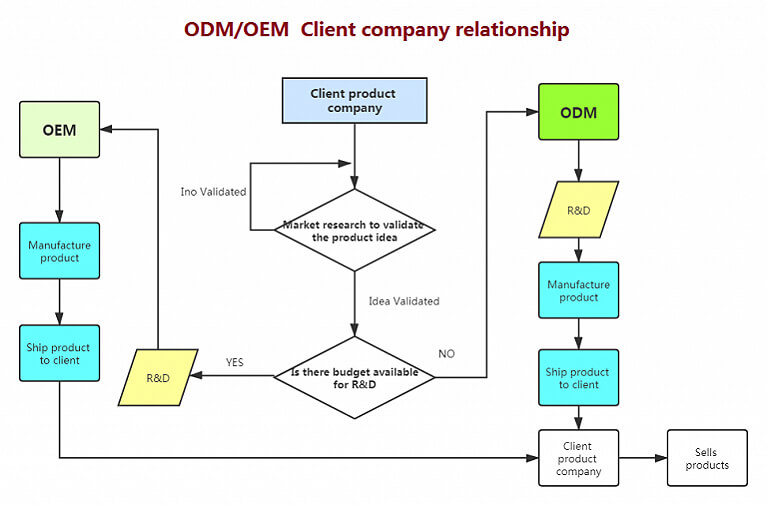

OEM and ODM are terms that are used a lot in the design and manufacturing industries. Many people don’t know what the difference is between these two terms, though, because they sound very similar. Different ways of making things are described by the terms ODM and OEM. The difference between these two production systems is how much the brand owner is involved in designing, engineering, and making the product.

What is ODM?

ODM stands for “Original Design Manufacturer.” This is a company that can design, develop, make, and sell its own products. Most of the time, ODMs design and develop products on their own or with the help of customers. All you have to do is tell them what kind of design you want, and they’ll show you what they already have so you can choose.

What is OEM?

OEM stands for “original equipment manufacturer,” which is a company that develops, builds, or sells products to another company or is in charge of distributing its products in a way that meets the standards of that company. For example, Apple designed and made the iPhone and then gave Foxconn permission to make it.

If you are a manufacturer, you can’t design, make, test, and brand your own products. Instead, you should offer OEM manufacturing and basic manufacturing services to help companies make products in large quantities.

Advantage of ODM & OEM

ODM

1. For R&D and setting up a custom production line, you don’t have to spend a lot of money up front.

2. Mold costs don’t have to be controlled, which can save a lot of money.

3. You can put more of your attention on selling your product.

4. Don’t worry about having the right skills or resources to make your design work.

5. Even if you only buy a few things, you can still save money. This is because ODMs usually make a lot of a product to sell in small amounts.

6. OEM is often faster to market.

OEM

1. You will own all rights to your ideas. The copyright on your product specifications will also be protected.

2. You can quickly get a quote from the manufacturer because you will have clear designs and specifications.

3. You can make better deals and switch easily to other suppliers.

4. Your product might be harder to copy

5. Working prototypes lower the risk of making the product.

How to Start Your OEM and ODM Service

If you want to start an OEM or ODM business, here are some things to think about:

What do you have to offer, and where can you add value?

Do you know how to create, build, and test products?

Is it easier for you to make something based on a design brief than to spend time and money making something yourself?

How quickly can you make things, and are there any limits?

How can you make a client feel at ease when doing business with you?

Do you have legal documents in place to protect your team and property?

continue reading

Related Posts

According to product design, once you decide to use CNC to process the product, you should choose the best material, whether it is metal, plastic

According to product design, once you decide to use CNC to process the product, you should choose the best material, whether it is metal, plastic

According to product design, once you decide to use CNC to process the product, you should choose the best material, whether it is metal, plastic