Sheet Metal Fabrication

We inspire our customers & support local businesses

Free Instant Quote

24H instant price & DFM

Fast Lead-time

Parts as Fast as 3 days

Quality Assurance

ISO9001:2015 Certified

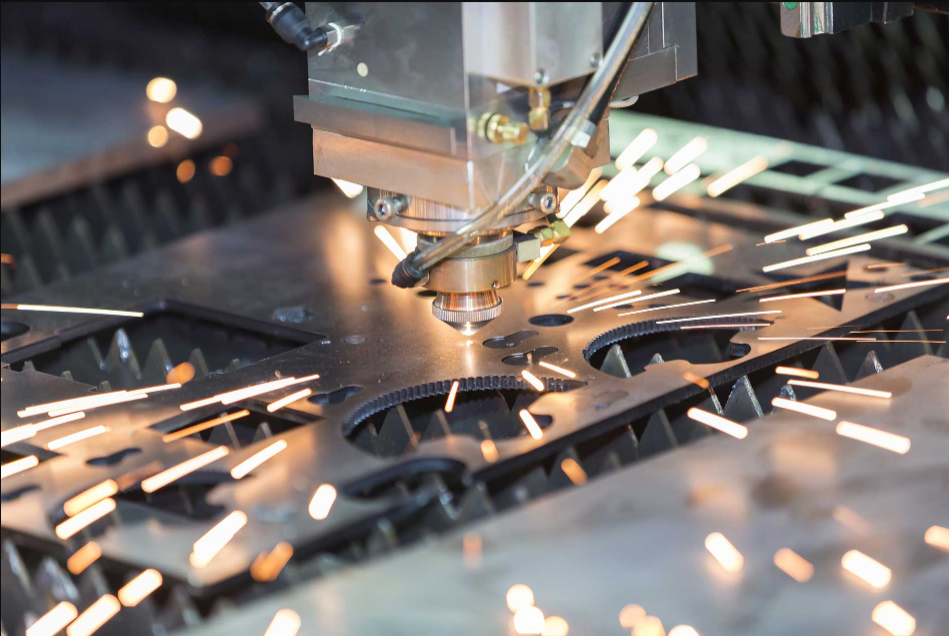

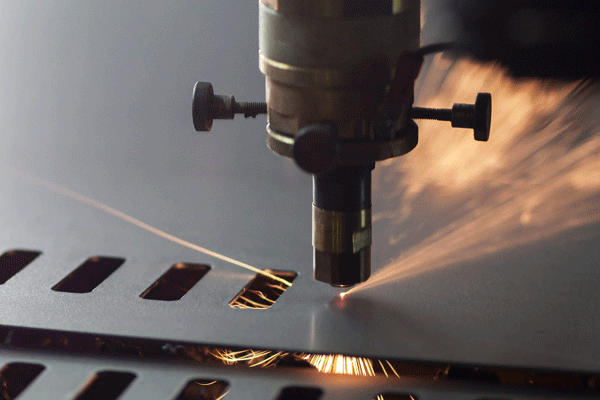

Gallery of Sheet Metal Fabrication

Whether you need complex mechanical components or simple metal structures, we provide fully customized solutions.

htsin precision

Sheet Metal Fabrication Capabilities

Our standard tolerances for custom CNC machining of metals is DIN-2768-1-m and for plastics is DIN-2768-1-c. Tolerances are greatly affected by part geometry and type of material. For case-by-case studies, please contact us with email for details.

| Feature | Description |

|---|---|

| Blank Size | 10’ x 20’ (3.05 m x 6.10 m). We accommodate larger part volumes upon request. |

| Standard Lead Time | 3 business days |

| Sheet Thickness | 0.024” – 0.250” typical. We accommodate thicker or thinner gauges upon request. |

| General Tolerances | For single planes or flat parts, +/- 0.010” on edge to edge, edge to hole, and hole to hole features; +/- 0.010” on bend to edge/hole features. For multi-planed bent parts, +/- 0.030” for hole to hole/edge, edge to edge, and over-formed parts; +/- 1 degree for bend angles. |

| Braking (Hydraulic) | 10’ length, fingers from 3” – 6” |

| Braking (Magnetic) | 6 tons of magnetic pull across the entire beam, 5/8″ minimum reverse bend |

| Punching | 2″ diameter hole capacity, or larger upon request |

| Welding | Welded edges and seams, weldments, and assemblies |

why you choose Htsin Precision

Htsin Precision is your premier cnc turning company for precision CNC turning services, delivering more than just quality products.

Sheet Metal Fabrication

Advanced equipment: We have advanced laser cutting machines, stamping machines, bending machines, welding machines, etc. to ensure processing accuracy and efficiency.

Experienced team: We have a team of experienced engineers and technicians to provide you with professional technical support and services.

Strict quality control: We strictly implement the ISO 9001 quality management system to ensure that product quality meets your requirements.

5000+

CNC Turning Projects

500+

Satisfied customers

350+

Highly qualified employees

100+

Advanced CNC Turning Machines

Quality Assurance

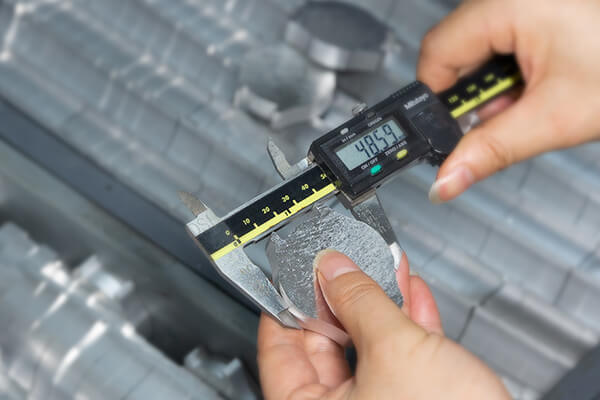

With more than 20 years of manufacturing and processing experience, we already have a complete production and processing process and quality control system, and carry out strict inspections on materials, processing, finished products, shipments and other links to ensure product quality and on-time delivery. The company has passed a number of quality management system certifications, and has been committed to providing customers with efficient and high-quality products and services.

Material inspection

We carry out quality certificate and composition analysis inspection on purchased materials

Completion inspection

Final inspection in the testing laboratory, more quality control process, until the product meets the requirements

Service first, firmly believe that product quality is the life of the enterprise, the pursuit of excellence in quality, the perfect products and services to provide customers, to win customer satisfaction.

John Deo – CEO ABCWorks