Available Surface Finishes for You Choosing

In order to make your product stand out on the shelf, we apply integrated creative surface surface treatment to meet your requirements. Our own factories and the establishment of the supply network shorten the process. Use standards for texture to ensure plastic injection or high -quality surface decorative surface of metal parts

| Picture | Name | Description | Materials | Color | Texture | Column 7 |

|---|---|---|---|---|---|---|

As machined |

As-machined | The “as machined” finish, which is the standard for our parts, has a surface roughness of 3.2 m (126 in). This smooths out sharp edges and removes burrs from the parts. | All materials | n/a | Stain | Get Instant Quote>> |

bead blasting |

Bead Blasting | Bead blasting is the process of pushing a strong stream of blast media against a surface, usually with high pressure and a lot of force, to remove unwanted coating layers and surface dirt. | Aluminum, Steel, Stainless Steel, Brass, Copper | n/a | Matte | Get Instant Quote>> |

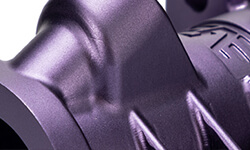

anodizing |

Anodizing | By stopping corrosion and wear, our anodizing process keeps our parts in good shape for a long time. It also looks great and is a great surface treatment for painting and priming. | Aluminum | Clear, black, grey, red, blue, gold | Smooth, matte finish | Get Instant Quote>> |

|

Electroplating | By using electric currents to reduce metal cations, electroplating protects the surface of parts and keeps rust and other flaws from causing them to deteriorate. | Aluminum, steel, stainless steel | Gold, silver, nickel, copper, brass | Smooth, glossy finish | Get Instant Quote>> |

polishing |

Polishing | During polishing, an abrasive material is used to rub the surface of the part to make it shine more or less, depending on your needs. This ranges from Ra 0.8 to Ra 0.1. | All materials | n/a | Smooth, glossy finish | Get Instant Quote>> |

powerd coating |

Powder Coating | Using corona discharge, we get the powder coating to stick to the part. This makes a layer that is more resistant to wear and has a typical thickness of 50 to 150 μm. | All metal materials | Custom | Glossy | Get Instant Quote>> |

brushing |

Brushing | Brushing is a way to treat the surface of something by making marks on it with abrasive belts. This is usually done for aesthetic reasons. | ABS, Aluminum, Brass, Stainless Steel, Steel | n/a | Satin | Get Instant Quote>> |

painting |

Painting | When you paint something, you spray a layer of paint onto the part. The customer can match the colors to any Pantone color number, and the finishes can be matte, glossy, or metallic. | Aluminum, Stainless Steel, Steel | Custom | Gloss, semi-gloss, flat, metallic, textured | Get Instant Quote>> |

black oxide |

Black Oxide | Black oxide is a coating that is used to change the color of steel and stainless steel. It is similar to alodine. It is mostly used for how it looks and to protect against mild corrosion. | Steel, Stainless Steel | Black | Smooth, matte | Get Instant Quote>> |

alodine |

Alodine | Chromate conversion coating, also called Alodine, is a chemical coating that stops aluminum from corroding and makes it passivate. It’s also used as a base layer before parts are primed and painted. | Aluminum | Clear, Gold | Same as before | Get Instant Quote>> |

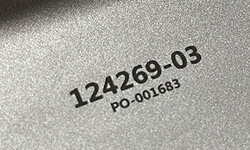

part marking |

Part Marking | Part marking is a cheap way to add logos or custom lettering to your designs. It is also often used for custom part tagging during large-scale production. | All materials | Custom | n/a | Get Instant Quote>> |