Die Casting

We inspire our customers & support local businesses

Free Instant Quote

24H instant price & DFM

Fast Lead-time

Parts as Fast as 3 days

Quality Assurance

ISO9001:2015 Certified

Achieve Your Goals

with Htsin Precision

For two decades, Htsin Precision has been a symbol of excellence in the realm of precision parts manufacturing. Embarking on our journey 20 years ago, we committed ourselves to the ethos of quality, precision, and unparalleled service. Over these years, we’ve navigated the evolving landscape of manufacturing, continuously adapting, learning, and perfecting our craft. Our expertise in die casting is a testament to this dedication. Clients who choose Htsin Precision are not merely availing a service; they’re benefiting from a legacy built on two decades of relentless pursuit of excellence. Our experience is not just a measure of time; it’s a stamp of our expertise, reliability, and commitment to pushing the boundaries of what’s possible in precision manufacturing.

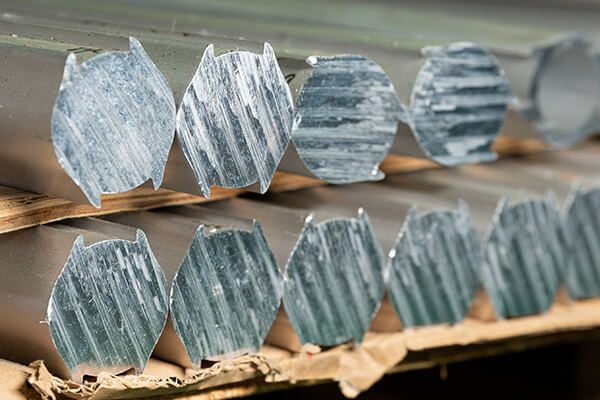

Die casting stands as one of the most efficient and versatile methods for producing metal parts and components. At its core, the die casting process involves forcing molten metal under high pressure into mold cavities or “dies.” These dies are typically made from hardened tool steel, crafted with precision to define the shape of the desired part. Once the metal solidifies, the die is opened to release the cast part. This method is favored for its ability to produce parts with complex shapes, tight tolerances, and smooth finishes directly from the mold, minimizing the need for post-processing.

Gallery of Die Casted Parts

Whether you’re a budding business or a renowned brand, we’re here to help you develop CNC-turned parts. Check our extensive library of completed parts to see what we’re capable of.

why you choose Htsin Precision

Htsin Precision is your premier cnc turning company for precision CNC turning services, delivering more than just quality products.

Our Strengths in Die Casting

- Consistent Quality: Maintaining uniformity across large production batches.

- Custom Solutions: Tailored die casting methods to meet specific client needs.

- Cost-Effective: Offering competitive pricing without compromising on quality.

- Innovative Techniques: Staying abreast of the latest in die casting technology.

20000+

CNC milled Projects

500+

Satisfied customers

350+

Highly qualified employees

400+

Advanced CNC Milling Machines

Quality Assurance

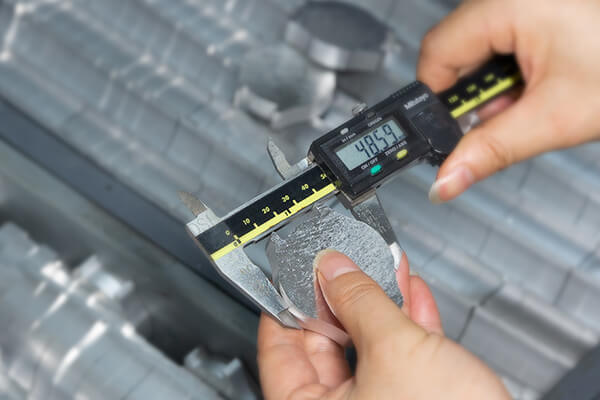

With more than 20 years of manufacturing and processing experience, we already have a complete production and processing process and quality control system, and carry out strict inspections on materials, processing, finished products, shipments and other links to ensure product quality and on-time delivery. The company has passed a number of quality management system certifications, and has been committed to providing customers with efficient and high-quality products and services.

Material inspection

We carry out quality certificate and composition analysis inspection on purchased materials

Completion inspection

Final inspection in the testing laboratory, more quality control process, until the product meets the requirements

Service first, firmly believe that product quality is the life of the enterprise, the pursuit of excellence in quality, the perfect products and services to provide customers, to win customer satisfaction.

John Deo – CEO ABCWorks