SWISS CNC Machining

We inspire our customers & support local businesses

Free Instant Quote

24H instant price & DFM

Fast Lead-time

Parts as Fast as 3 days

Quality Assurance

ISO9001:2015 Certified

Achieve Your Goals

with Htsin Precision

Htsin Precision is not just a name, but a legacy built over two fruitful decades in the realm of custom machining. Over these 20 years, we have honed our craft, embraced technological advancements, and have been at the forefront of delivering top-notch Swiss CNC machined parts. Our journey is one of relentless pursuit of perfection, and our storied past speaks volumes of our commitment to quality, precision, and customer satisfaction. Clients who partner with Htsin Precision aren’t just availing a service; they’re becoming part of a rich tapestry of expertise and excellence that has been woven over 20 years. Our legacy is a testament to our dedication, and as we look to the future, we remain committed to pushing the boundaries of what’s possible in Swiss CNC machining.

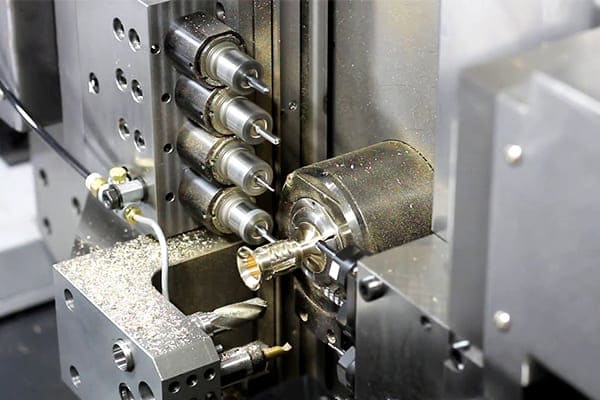

Swiss CNC machining is a specialized method of machining that stands out for its ability to produce intricate, high-precision components. Originating from the Swiss watch-making industry, this technique employs a unique sliding headstock operation where the workpiece is supported very close to the cutting tool, minimizing deflection and vibrations. As a result, Swiss CNC machines can achieve impeccable accuracy and are especially suited for crafting long, slender parts or when tight tolerances are imperative.

Gallery of SWISS CNC Machined Parts

Whether you’re a budding business or a renowned brand, we’re here to help you develop CNC-turned parts. Check our extensive library of completed parts to see what we’re capable of.

why you choose Htsin Precision

Htsin Precision is your premier cnc turning company for precision CNC turning services, delivering more than just quality products.

Our Strengths in Swiss CNC Machining

- Precision: Delivering components with unparalleled accuracy.

- Consistency: Ensuring uniformity across large production batches.

- Flexibility: Capable of handling diverse client requirements and designs.

- Scalability: From prototyping to mass production, we’ve got you covered.

- Quality Assurance: Rigorous quality checks to maintain industry-leading standards.

20000+

CNC milled Projects

500+

Satisfied customers

350+

Highly qualified employees

400+

Advanced CNC Milling Machines

1st Approach We Follow

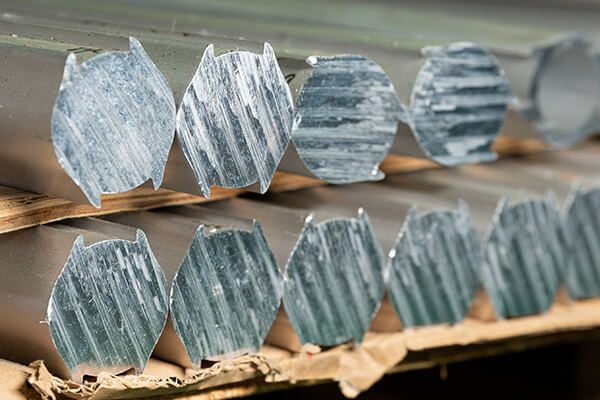

Machinable Materials

- Metals: Stainless steel, aluminum, brass, titanium, etc.

- Plastics: PEEK, Delrin, Nylon, and more.

- Special Alloys: Discuss any unique or proprietary alloys you can machine.

- Material Benefits: Brief on why certain materials are preferred in specific applications.

2nd Approach We Follow

High Tolerance

Our standard tolerances for custom CNC machining of metals is DIN-2768-1-m and for plastics is DIN-2768-1-c. Tolerances are greatly affected by part geometry and type of material. For case-by-case studies, please contact us with email for details.

| Type | Tolerance |

|---|---|

| Linear dimension | +/- 0.025 mm |

| Hole diameters (not reamed) | +/- 0.025 mm |

| Shaft diameters | +/- 0.025 mm |

| Part size limit | 950 * 550 * 480 mm |

3rd Approach We Follow

Surface Treatments

- Polishing: Achieving mirror-like finishes.

- Anodizing: For enhanced durability and appearance.

- Plating: Gold, silver, nickel, and other plating options.

- Heat Treatments: Enhancing material properties.

- Additional Treatments: Any other specialized treatments you offer.

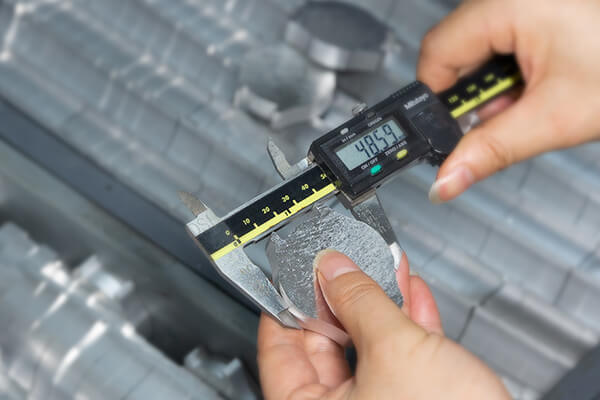

Quality Assurance

With more than 20 years of manufacturing and processing experience, we already have a complete production and processing process and quality control system, and carry out strict inspections on materials, processing, finished products, shipments and other links to ensure product quality and on-time delivery. The company has passed a number of quality management system certifications, and has been committed to providing customers with efficient and high-quality products and services.

Material inspection

We carry out quality certificate and composition analysis inspection on purchased materials

Completion inspection

Final inspection in the testing laboratory, more quality control process, until the product meets the requirements

Service first, firmly believe that product quality is the life of the enterprise, the pursuit of excellence in quality, the perfect products and services to provide customers, to win customer satisfaction.

John Deo – CEO ABCWorks