OEM Manufacturing

We inspire our customers & support local businesses

Free Instant Quote

24H instant price & DFM

Fast Lead-time

Parts as Fast as 3 days

Quality Assurance

ISO9001:2015 Certified

Professional OEM Manufacturer in China

Htsin Precision is a leading custom metal parts manufacturing company, we specialize in 3CD electronic product parts manufacturing, specializing in manufacturing precision components of various sizes and shapes for original equipment manufacturers (OEM), widely used in mobile phones, watches, headphones, power supplies , speakers, lighting and other products.

Email Us For Reservations:

info@htsinprecision.com

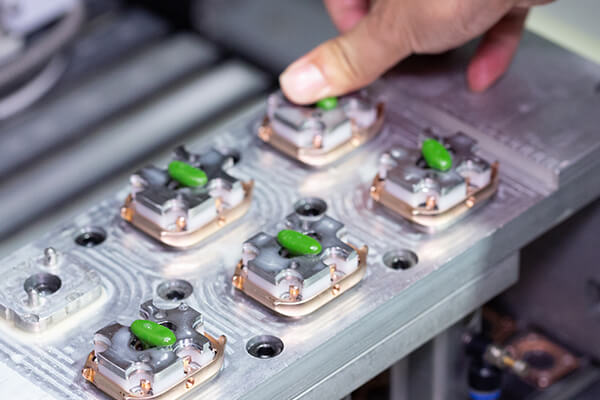

Gallery of OEM Parts

Whether you’re a budding business or a renowned brand, we’re here to help you develop CNC-turned parts. Check our extensive library of completed parts to see what we’re capable of.

Highest Quality Standard

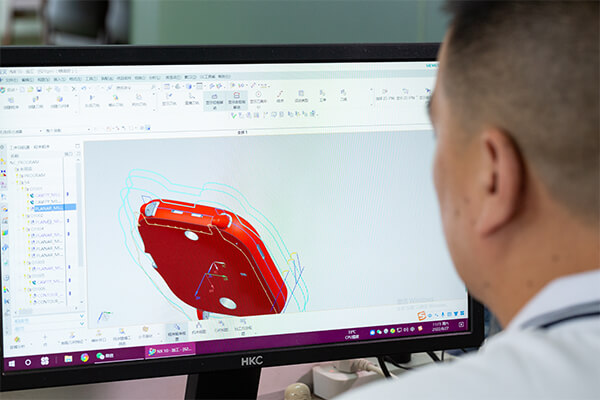

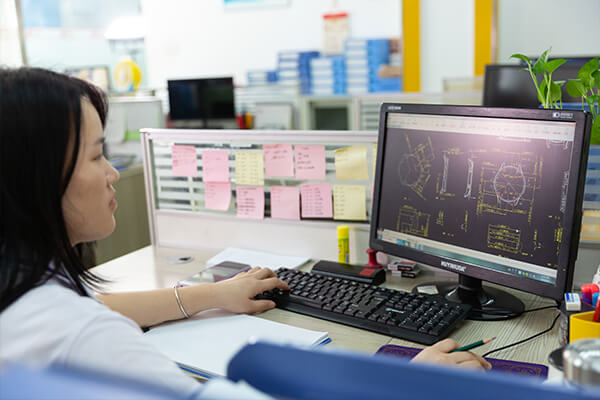

In HTSIN Precision Oem Manufacturer, we focus on the quality of all aspects of the process in order to provide high -quality products to our customers at a competitive price in time.

Qualtity Assurance

Why You Can Choose Us?

CNC Machining Workshop

Providing cost-effective and fast-paced prototyping and on-demand OEM parts manufacturing is at the heart of HTSIN PRECISION’s production philosophy. HTSIN PRECISION uses state-of-the-art CNC lathe machines to manufacture complex custom CNC turned parts from solid metals and plastics with exceptional surface finishes. From axial and radial holes to flats, grooves and slots, we can quickly manufacture these parts within 24 hours

2nd Approach We Follow

Tolerance

Our standard tolerances for custom CNC machining of metals is DIN-2768-1-m and for plastics is DIN-2768-1-c. Tolerances are greatly affected by part geometry and type of material. For case-by-case studies, please contact us with email for details.

| Type | Tolerance |

|---|---|

| Linear dimension | +/- 0.025 mm |

| Hole diameters (not reamed) | +/- 0.025 mm |

| Shaft diameters | +/- 0.025 mm |

| Part size limit | 950 * 550 * 480 mm |

Service first, firmly believe that product quality is the life of the enterprise, the pursuit of excellence in quality, the perfect products and services to provide customers, to win customer satisfaction.

John Deo – CEO ABCWorks

How to work with us?

We strictly keep client data and information confidential, it is very easy and safe to work with us.