get to know us

Precision Tolerances: Why Microns Matter

In engineering, tolerance refers to the permissible variation in a dimension. While a consumer-grade part might accept ±0.1 mm, aerospace or medical components often require ±0.005 mm or tighter.

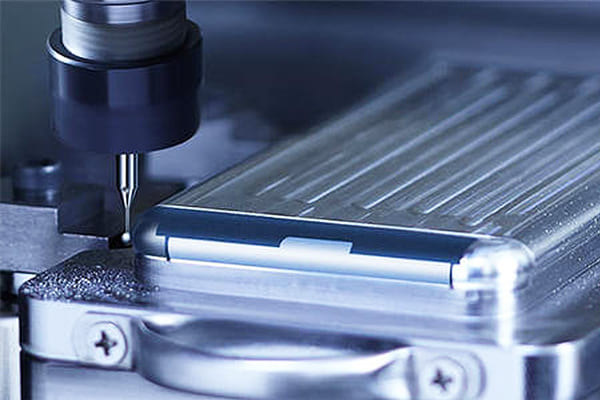

High Tolerance CNC Machining: We operate advanced 3-, 4-, and 5-axis CNC centers capable of micron-level accuracy.

Thermal Stability: Machine shops must control temperature during machining to prevent expansion or contraction affecting tolerances.

Inspection Routines: Our CMM (Coordinate Measuring Machine) verifies dimensions against CAD data, ensuring absolute accuracy before delivery.

Why It Matters for You: Tight tolerances directly impact performance, fit, and product lifespan—especially in high-load, high-speed, or safety-critical applications.

Material Mastery: From Titanium to PEEK

Complex geometry CNC machining is where engineering creativity meets manufacturing discipline.

5-Axis Machining: Allows for multi-face processing in a single setup, reducing error accumulation.

Thin-Walled Components: Requires careful vibration damping and toolpath optimization to avoid deformation.

Undercuts & Deep Cavities: Achieved through custom tool design and adaptive machining strategies.

With simulation-driven CAM programming, we ensure that even the most intricate designs are machinable without compromising accuracy.

Why R&D Teams and Designers Trust Us

Engineering Partnership: We collaborate early in the design phase, offering Design for Manufacturability (DFM) feedback.

ISO 9001:2015 Certified: Consistent, documented quality control.

Rapid Prototyping & Low-Volume Production: Ideal for startups validating designs before mass production.

We don’t just machine parts—we help you bring your vision from CAD to reality.

continue reading

Related Posts

According to product design, once you decide to use CNC to process the product, you should choose the best material, whether it is metal, plastic

According to product design, once you decide to use CNC to process the product, you should choose the best material, whether it is metal, plastic

According to product design, once you decide to use CNC to process the product, you should choose the best material, whether it is metal, plastic