get to know us

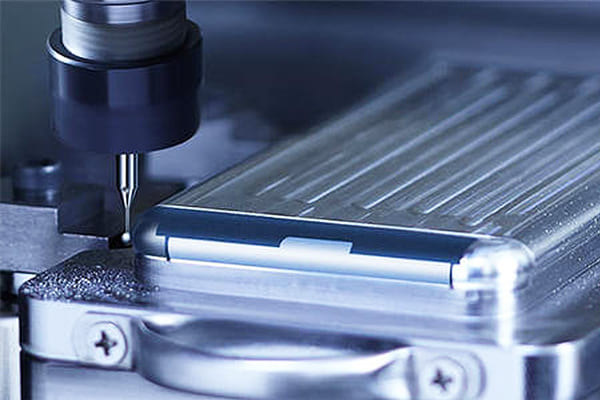

The Hidden Challenge: Thermal Deformation in Precision Machining

When machining at micron-level tolerances, even the smallest temperature fluctuation can lead to measurable deformation. For instance:

A 1°C temperature rise in a steel component can result in a dimensional change of up to 10 µm per meter, which is unacceptable in high-precision applications.

Heat can be generated by spindle rotation, cutting forces, and tool–workpiece friction, all of which compromise dimensional accuracy if not managed correctly.

Engineering Solutions for Thermal Control

Coolant Management Systems: Using advanced high-pressure or cryogenic coolants to minimize thermal load.

Adaptive Thermal Compensation: Modern CNC controllers integrate sensors to detect thermal drift and automatically adjust tool paths.

Machine Base Materials: Granite or polymer composites are often chosen for their low thermal expansion properties.

Environmental Control: Precision machining facilities maintain temperature stability within ±0.2°C, ensuring dimensional consistency.

Vibration: The Silent Precision Killer

Even with perfect thermal control, vibrations can deteriorate surface finish, damage tool life, and cause deviations from designed geometries. Sources of vibration include:

Spindle imbalance or tool wear

Floor-transmitted vibrations from nearby equipment

Resonance within machine structures

Advanced Vibration Control Methods

Dynamic Damping Systems: Smart dampers integrated into machine spindles or fixtures reduce oscillations in real time.

High-Rigidity Fixturing: Customized clamping solutions prevent micro-movements of the workpiece.

Isolated Foundations: Precision machines are often mounted on vibration-isolated platforms to eliminate floor resonance.

Digital Twin Simulation: Engineers use digital modeling to predict and suppress vibration modes before machining begins.

Achieving Micron-Level Accuracy: A Synergy of Engineering Disciplines

The ability to produce micron-level tolerances depends on integrating:

Thermal stability → Prevents dimensional drift.

Vibration suppression → Ensures flawless surface finish and geometric accuracy.

Material expertise → Metals like titanium and superalloys, or engineering plastics such as PEEK, require unique thermal and vibration strategies.

Process monitoring → Real-time data acquisition enables predictive maintenance and process optimization.

When machining at micron-level tolerances, even the smallest temperature fluctuation can lead to measurable deformation. For instance:

A 1°C temperature rise in a steel component can result in a dimensional change of up to 10 µm per meter, which is unacceptable in high-precision applications.

Heat can be generated by spindle rotation, cutting forces, and tool–workpiece friction, all of which compromise dimensional accuracy if not managed correctly.

Engineering Solutions for Thermal Control

Coolant Management Systems: Using advanced high-pressure or cryogenic coolants to minimize thermal load.

Adaptive Thermal Compensation: Modern CNC controllers integrate sensors to detect thermal drift and automatically adjust tool paths.

Machine Base Materials: Granite or polymer composites are often chosen for their low thermal expansion properties.

Environmental Control: Precision machining facilities maintain temperature stability within ±0.2°C, ensuring dimensional consistency.

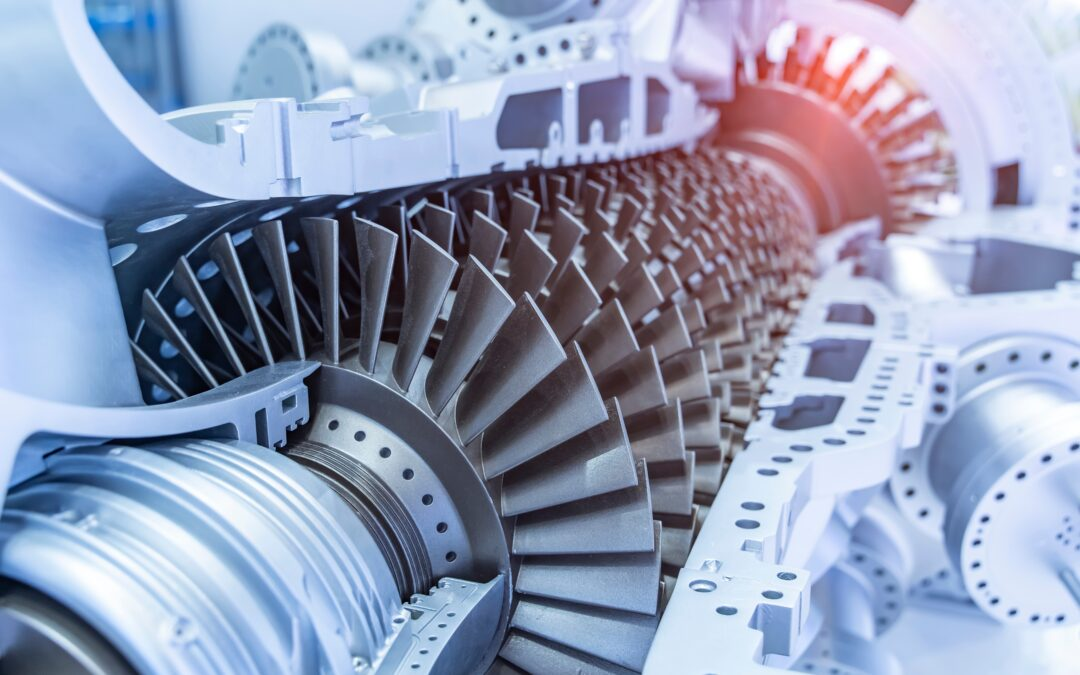

Why It Matters for High-Tech Industries

Aerospace & Defense: Turbine blades and structural components demand extreme reliability.

Optics & Photonics: Lens housings and reflective surfaces require nanometer-level finishes.

Semiconductors: Wafer handling and lithography equipment cannot tolerate dimensional errors.

Medical Devices: Surgical instruments and implants require repeatable high precision.

By mastering thermal and vibration control, machining providers demonstrate not only manufacturing capability but also engineering excellence, positioning themselves as trusted partners for high-value industries.

Ultra-precision machining is an interdisciplinary challenge that combines mechanical engineering, materials science, and process automation. At its core, achieving micron-level accuracy requires advanced control of thermal effects and vibration disturbances.

A manufacturing partner that invests in these engineering approaches ensures not just compliance with specifications but also the reliability, safety, and innovation demanded by today’s most advanced industries.

continue reading

Related Posts

According to product design, once you decide to use CNC to process the product, you should choose the best material, whether it is metal, plastic

According to product design, once you decide to use CNC to process the product, you should choose the best material, whether it is metal, plastic

According to product design, once you decide to use CNC to process the product, you should choose the best material, whether it is metal, plastic