get to know us

Discover how rapid manufacturing of precision parts is transforming the drone industry—ensuring lighter, stronger, and more efficient UAVs with faster time-to-market.

As artificial intelligence (AI) continues to revolutionize industries, the demand for high-performance hardware to support machine learning, robotics, and intelligent automation is growing rapidly. Behind the sleek algorithms and smart systems lies a critical enabler: custom machining. From prototype components to precision housings, CNC machining plays a vital role in bringing AI technologies to life.

What Are Precision Parts in Drones?

AI systems often require specialized hardware that off-the-shelf components cannot provide. Here’s why custom machining is indispensable:

Precision Tolerances: AI devices—such as robotic arms, sensor modules, and automated inspection systems—demand extremely tight tolerances to maintain performance and reliability.

Rapid Prototyping: The fast-paced development cycles in AI make rapid custom machining a must for creating and testing new designs efficiently.

Thermal and Mechanical Demands: Custom metal housings or heat sinks machined from aluminum or copper help manage the heat generated by high-performance chips or GPUs.

Lightweight, Durable Materials: Custom parts are often made from aerospace-grade materials like titanium or high-strength plastics to support both durability and low weight in mobile AI platforms.

Applications of CNC Machining in AI SystemsCNC

1. Robotics and Automation

Precision-machined joints, brackets, and frames ensure smooth and stable movement in AI-driven robots. Custom CNC parts help maintain alignment and functionality over time.

2. Computer Vision & Smart Cameras

Camera housings and mounting systems for AI vision are often custom-machined to ensure proper alignment and protection in industrial or outdoor environments.

3. AI-Powered Medical Devices

In AI-driven diagnostic tools or robotic surgical assistants, high-precision machined components ensure safe and reliable performance, especially in life-critical applications.

4. Edge Computing Devices

AI is moving closer to the edge. CNC-machined enclosures for compact AI chips and edge servers provide thermal management and electromagnetic shielding.

5. Autonomous Systems (Drones, Vehicles)

AI navigation systems in UAVs and self-driving cars rely on lightweight, durable, and vibration-resistant machined components for sensors, frames, and mounts.

Benefits of Choosing Custom Machining for AI Applications

Design Flexibility: Tailor components to fit specific AI devices or hardware platforms.

Faster Time-to-Market: Rapid prototyping shortens the R&D cycle.

Scalable Production: Whether for a prototype or small-batch production, machining scales with project needs.

High Reliability: CNC-machined parts maintain consistent quality across complex designs.

Precision parts are meticulously machined components that meet extremely tight tolerances—often within microns. In drone applications, they typically include:

Motor housings and mounts

Lightweight frames and arms

Camera and sensor brackets

Landing gear and connectors

Propeller hubs and shafts

These parts demand not only dimensional accuracy but also material performance under vibration, pressure, and extreme temperatures.

The Role of Rapid Manufacturing

Rapid manufacturing uses advanced machining technologies to produce parts quickly without compromising quality. For drone components, this means:

Short lead times – From prototype to production in days, not weeks.

Design flexibility – Easy updates or customizations during development.

Low-to-medium volume capability – Ideal for small batch UAV production.

Reduced cost-to-market – Faster iteration saves both time and money.

Key Technologies Used

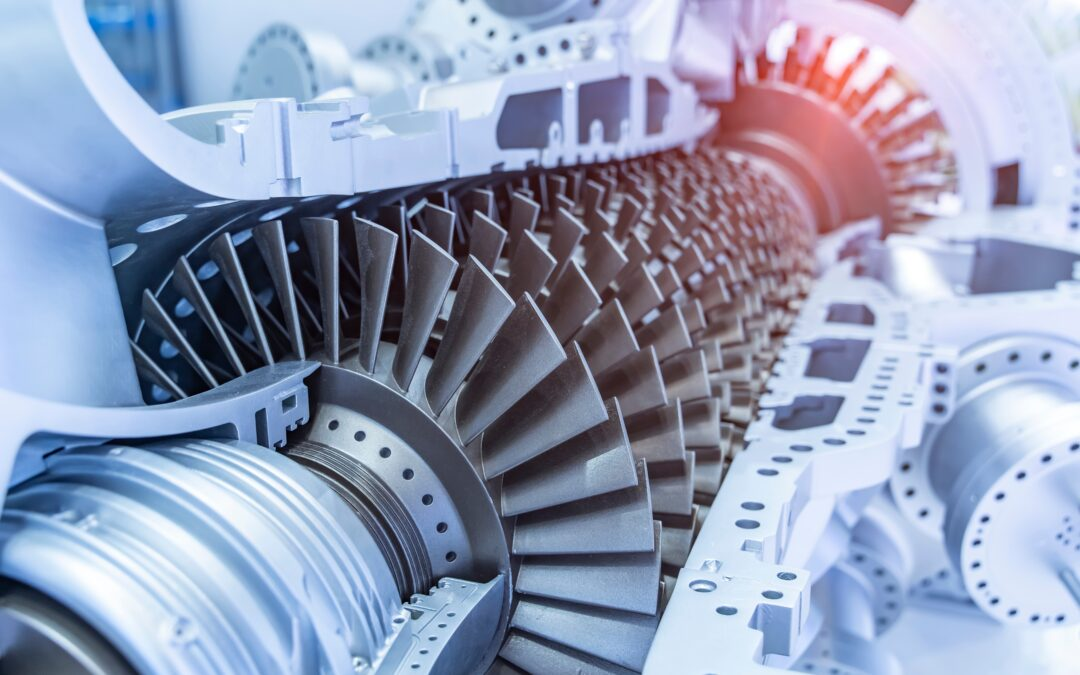

CNC Machining

CNC (Computer Numerical Control) machining offers high precision, tight tolerance control, and repeatability—ideal for aluminum or titanium drone parts.

3D Printing (Additive Manufacturing)

Perfect for lightweight plastic or composite parts. Rapid prototyping with functional-grade materials accelerates product testing.

Sheet Metal Fabrication

For structural drone parts, sheet metal provides strength and rigidity with low weight, ideal for custom enclosures and support frames.

Precision parts are meticulously machined components that meet extremely tight tolerances—often within microns. In drone applications, they typically include:

Motor housings and mounts

Lightweight frames and arms

Camera and sensor brackets

Landing gear and connectors

Propeller hubs and shafts

These parts demand not only dimensional accuracy but also material performance under vibration, pressure, and extreme temperatures.

Choosing the Right Manufacturing Partner

When selecting a manufacturing partner for drone parts, consider:

Experience with aerospace-grade tolerances

Capability for small batch and fast turnaround

Material selection guidance and certifications

Online quoting and real-time production tracking

Fly Faster with Precision Manufacturing

As the drone industry soars to new heights, the demand for high-quality, rapidly manufactured precision parts continues to grow. Whether you’re developing a next-gen UAV or refining a prototype, partnering with an expert in fast-turn CNC machining, 3D printing, and sheet metal fabrication ensures your drone is ready for lift-off—quickly and reliably.

continue reading

Related Posts

According to product design, once you decide to use CNC to process the product, you should choose the best material, whether it is metal, plastic

According to product design, once you decide to use CNC to process the product, you should choose the best material, whether it is metal, plastic

According to product design, once you decide to use CNC to process the product, you should choose the best material, whether it is metal, plastic