get to know us

Looking for custom precision machining of turbine blades from 5mm to 200mm? We specialize in high-accuracy manufacturing of critical components for aerospace, energy, and industrial sectors.

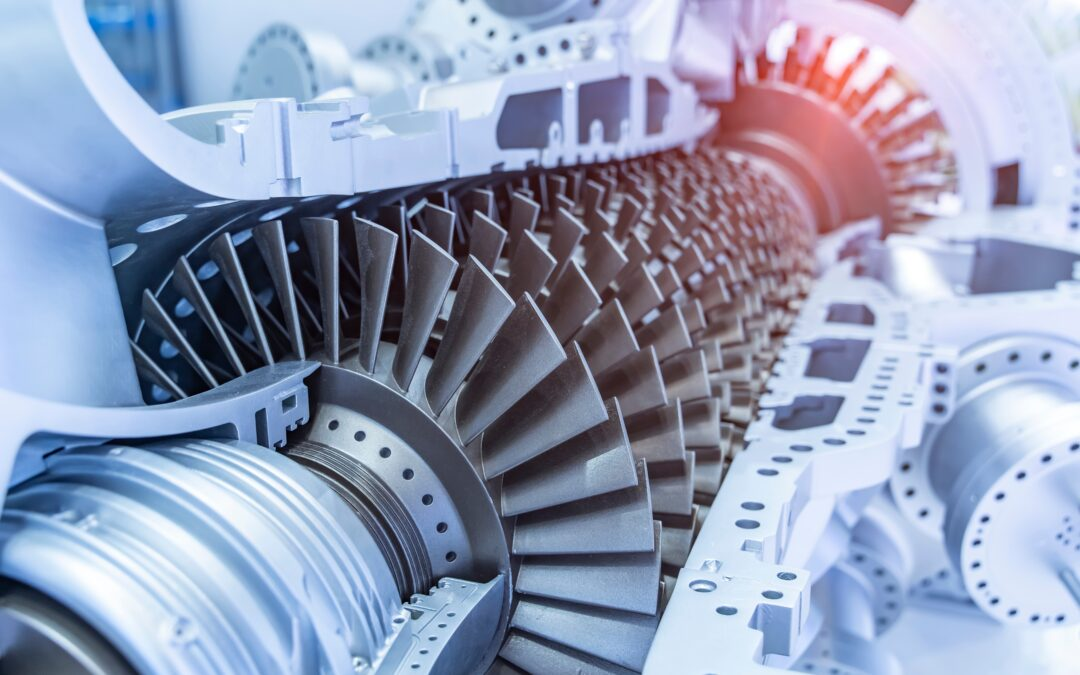

Introduction: Precision That Drives Performance

Turbine blades are among the most mission-critical components in any mechanical system—whether in aerospace engines, power generation, or high-performance industrial machinery. Their complex geometries, demanding tolerances, and material challenges require a level of expertise few machining facilities can offer.

At [Your Company Name], we specialize in precision CNC machining of turbine blades ranging from 5mm to 200mm, delivering customized core components for global clients across various high-stakes industries.

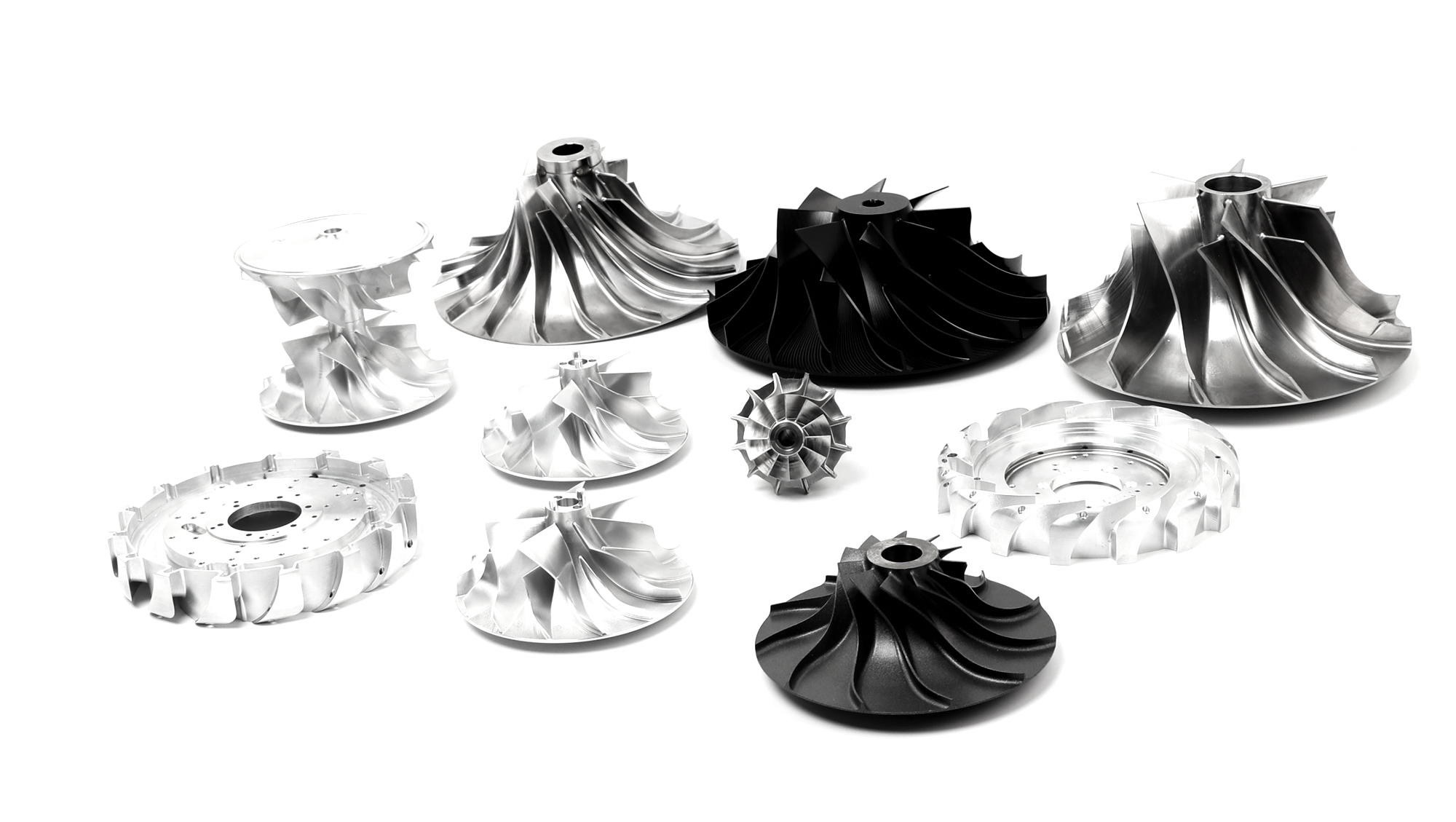

Wide Range of Blade Sizes: From Micro to Heavy-Duty

Our capability to machine turbine blades from 5mm to 200mm allows us to serve a wide range of applications:

5mm–30mm Micro Blades:

Ideal for compact systems like drones, dental turbines, or microturbines

30mm–100mm Mid-Sized Blades:

Commonly used in medical equipment, HVAC systems, and robotics

100mm–200mm Large Blades:

Suitable for aerospace engines, industrial gas turbines, and renewable energy systems

No matter the size, we ensure tight tolerances, consistent profiles, and high surface integrity.

Precision Machining Capabilities

To manufacture turbine blades that perform reliably at high speeds and temperatures, we employ:

✅ 5-Axis CNC Machining

Perfect for complex aerodynamic shapes and twisted blade profiles

✅ High-Temperature Material Expertise

Capable of machining Inconel, Titanium, Stainless Steel, Aluminum, and heat-resistant alloys

✅ Tight Tolerances & Surface Finish

Dimensional tolerances up to ±0.005 mm

Surface finishes down to Ra 0.4 μm

Polishing, bead blasting, and protective coatings available

✅ Custom Fixturing & CAM Programming

For accurate repeatability and optimal cutting angles, especially on thin airfoils and curved root forms

Industries We Serve

Our turbine blade machining services support critical operations in:

Industry Application

Aerospace Jet engine blades, auxiliary turbines

Power Generation Steam & gas turbines, microturbines

Renewable Energy Wind turbine micro-components

Automotive R&D Turbocharger rotors, test turbines

Industrial Systems HVAC, compressed air systems, tooling turbines

Every part is made to fit, function, and last—under high heat, stress, and rotational force.

Why Choose Us for Turbine Blade Machining?

🔹 Flexible Size Range – From miniature to large-scale blades

🔹 High Precision Expertise – 5-axis programming, simulation, and CAM optimization

🔹 Material Mastery – Capable of working with exotic and aerospace-grade alloys

🔹 Strict Quality Control – CMM inspection, balance testing, dimensional reports

🔹 Engineering Support – DFM (Design for Manufacturability) guidance and technical consultation

We don’t just manufacture blades—we help you optimize performance from concept to production.

Quality and Certification

We operate under strict quality protocols, including:

ISO 9001:2015 Certified QMS

Material traceability (EN 10204 3.1)

First Article Inspection (FAI)

Balance and concentricity testing for rotational parts

continue reading

Related Posts

According to product design, once you decide to use CNC to process the product, you should choose the best material, whether it is metal, plastic

According to product design, once you decide to use CNC to process the product, you should choose the best material, whether it is metal, plastic

According to product design, once you decide to use CNC to process the product, you should choose the best material, whether it is metal, plastic