get to know us

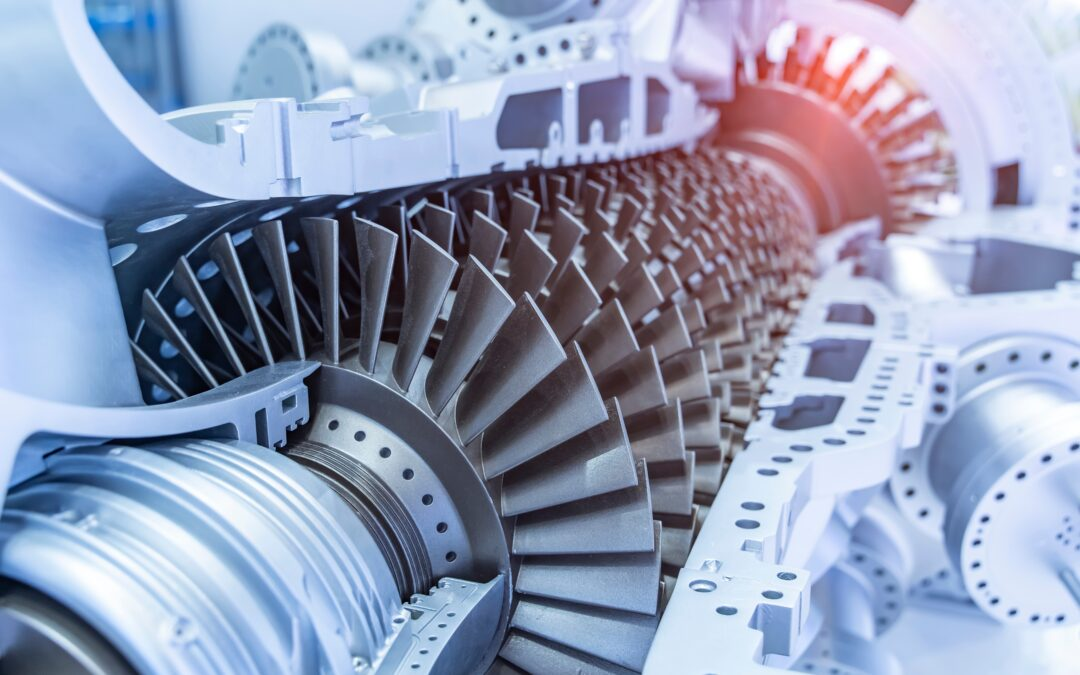

Precision Machining Powers the New Energy Industry

Explore how precision machining meets the growing demands of the new energy industry—supporting EVs, wind turbines, solar systems, and more with high-quality custom components.

Introduction: Precision Machining Meets the New Energy Revolution

As the world shifts toward sustainable power, the new energy industry—including electric vehicles (EVs), solar, wind, and hydrogen technologies—is booming. Behind this rapid development is a growing need for high-precision, custom-machined components that ensure performance, safety, and efficiency.

From EV motor housings to wind turbine gearbox parts, precision machining plays a critical role in enabling innovation, scalability, and reliability in the energy sector.

Why the New Energy Industry Relies on Precision Machining

The new energy sector demands parts that are:

Highly accurate – Often within microns, to maintain efficiency and reduce energy loss.

Material-specific – Using aluminum, copper, stainless steel, titanium, or composites.

Durable and long-lasting – Withstand harsh environments, vibration, and temperature changes.

Custom-engineered – For unique applications and emerging technologies.

Key Applications of CNC Machining in New Energy

Electric Vehicles (EVs):

Battery enclosures and trays

Heat sinks and cooling plates

Motor shafts and housings

Lightweight structural frames

Wind Energy:

Gearbox housings

Rotor hubs

Brake system components

Bearing mounts

Solar Power Systems:

Mounting brackets

Inverter casings

Cooling elements

Connection terminals

Hydrogen & Fuel Cells:

Bipolar plates

Compressor components

Valve bodies and manifolds

Sensor and control housings

How Rapid Manufacturing Supports Innovation

Rapid CNC machining and prototyping allow energy tech companies to:

Accelerate product development

Test and iterate designs faster

Meet tight project deadlines

Scale from prototype to low-volume production easily

Especially in early-stage or pilot projects, fast-turnaround machining helps shorten the innovation cycle and bring clean technologies to market quicker.

Challenges & Solutions in New Energy Machining

Challenge Solution

High mix, low volume demand Flexible CNC setups and fast quoting systems

Exotic materials (e.g., titanium, Inconel) Advanced tooling and material expertise

Complex geometries 5-axis machining and CAD/CAM integration

Sustainability requirements Low-waste processes and recyclable metal use

Choosing the Right Machining Partner for Clean Energy Projects

To support demanding energy applications, a machining partner should offer:

Experience with energy and automotive components

Capability in multi-material, tight-tolerance parts

ISO/AS certifications and quality assurance

Engineering support from prototype to production

Machining the Future of Energy

As the energy transition continues, precision machining stands as a backbone of clean-tech innovation. Whether you’re developing EV battery systems, wind turbine assemblies, or hydrogen fuel cell components, precision CNC machining ensures your parts are built to perform, built to last, and built on time.

continue reading

Related Posts

According to product design, once you decide to use CNC to process the product, you should choose the best material, whether it is metal, plastic

According to product design, once you decide to use CNC to process the product, you should choose the best material, whether it is metal, plastic

According to product design, once you decide to use CNC to process the product, you should choose the best material, whether it is metal, plastic