get to know us

In today’s competitive manufacturing environment, companies demand more than just high-quality components—they need reliability, speed, and a partner who understands complex custom requirements from start to finish. That’s where end-to-end precision CNC machining services come in.

At HTSINPRECISION, we provide a full-spectrum machining solution—from digital design consultation to delivering finished, inspection-certified parts. Our integrated workflow ensures optimal precision, efficiency, and repeatability across industries such as aerospace, medical, robotics, and energy.

Digital Design & Engineering Collaboration

Every successful part begins with a well-optimized design. Our engineering team works closely with your CAD/CAM files, offering DFM (Design for Manufacturability) suggestions to enhance machinability, reduce costs, and shorten lead times.

Support for STEP, IGES, SolidWorks, and custom formats

Tolerance optimization and risk prediction

Material consulting based on application scenario

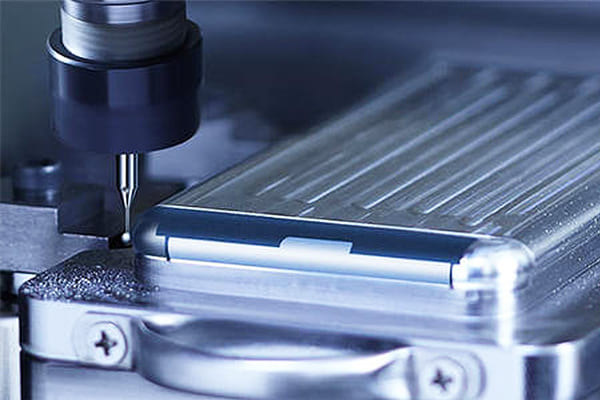

Multi-Axis CNC Machining for Complex Geometries

Our advanced CNC machining centers, including 3-axis, 4-axis, and 5-axis machines, allow us to handle intricate parts with exceptional accuracy and repeatability.

Precision tolerances down to ±0.005mm

Compatible with aluminum, stainless steel, titanium, and engineered plastics

Capable of high-mix low-volume or batch production

Whether it’s thin-walled aerospace components, custom enclosures, or medical-grade parts, we deliver tight-tolerance results with consistent quality.

In-Process & Final Quality Inspection

We maintain ISO 9001:2015-certified quality systems and apply rigorous inspections throughout the machining process. Each component is checked for dimensional accuracy, surface finish, and functional performance.

CMM (Coordinate Measuring Machine) inspection

Surface roughness testing and material traceability

First Article Inspection (FAI) upon request

Packaging & On-Time Global Delivery

Once parts are approved, our team ensures they are safely packaged and ready for global shipment. With robust logistics support, we offer on-time delivery to North America and Europe, with tracking and full documentation included.

Custom packaging based on part geometry

International shipping with Incoterms (FOB, DDP, EXW)

Multilingual communication support

Why Choose Us for End-to-End CNC Machining?

One-stop service: From drawing to delivery

Fast response & flexible MOQ

Experienced in handling complex, high-precision parts

Trusted by clients in aerospace, medical, robotics, and beyond

continue reading

Related Posts

According to product design, once you decide to use CNC to process the product, you should choose the best material, whether it is metal, plastic

According to product design, once you decide to use CNC to process the product, you should choose the best material, whether it is metal, plastic

According to product design, once you decide to use CNC to process the product, you should choose the best material, whether it is metal, plastic