get to know us

Discover how our CNC machining factory achieved ISO 9001:2015 certification and what it means for quality, reliability, and your custom precision machining projects.

Introduction: Quality You Can Trust

In precision CNC machining, consistency, traceability, and customer satisfaction are everything. That’s why leading manufacturers choose partners with proven quality systems.

At [Your Company Name], we’re proud to be ISO 9001:2015 certified, a milestone that highlights our commitment to professionalism, repeatable quality, and continuous improvement. In this article, we share not just how we earned this global standard—but why it matters to your project.

What Is ISO 9001:2015 and Why Does It Matter?

ISO 9001:2015 is the world’s most recognized quality management system (QMS) certification. It confirms that a company:

Has structured and documented processes for quality control

Continuously improves based on performance and customer feedback

Ensures traceability, accountability, and risk management

Puts customer satisfaction at the center of its operations

For CNC machining clients, this translates into:

Fewer defects

Faster delivery

Consistent part quality

Stronger supplier confidence

Our Certification Journey: Built on Real Manufacturing Strength

Earning ISO 9001:2015 is not just a checkbox—it’s a rigorous, months-long process. Our success reflects the deep operational strength we’ve built over years of precision manufacturing.

Key Factors Behind Our Certification:

✅ Documented Workflows:

From quoting to production to delivery, every process step is traceable and optimized.

✅ Inspection & Quality Control:

We implement CMM inspection, in-process checks, and final QC protocols to ensure every part meets spec.

✅ Skilled Workforce:

Our technicians and engineers are trained in advanced CNC programming, GD&T, and quality planning.

✅ Customer Feedback Loops:

We log and review all customer feedback to drive continuous improvement—just like ISO requires.

✅ Management Commitment:

Our leadership team made ISO 9001 a top strategic priority, investing in systems, training, and audits.

Why Our ISO 9001:2015 Certification Matters to You

When you choose a CNC supplier, you need more than just machines—you need a reliable partner who takes quality as seriously as you do.

Our ISO certification means:

Peace of mind that your parts will be delivered on time and to spec

Confidence that issues will be addressed quickly and transparently

Trust in a supplier who meets global quality benchmarks

Whether you’re ordering custom aerospace brackets, medical-grade housings, or low-volume plastic prototypes, our quality system ensures you get consistent, verified results—every time.

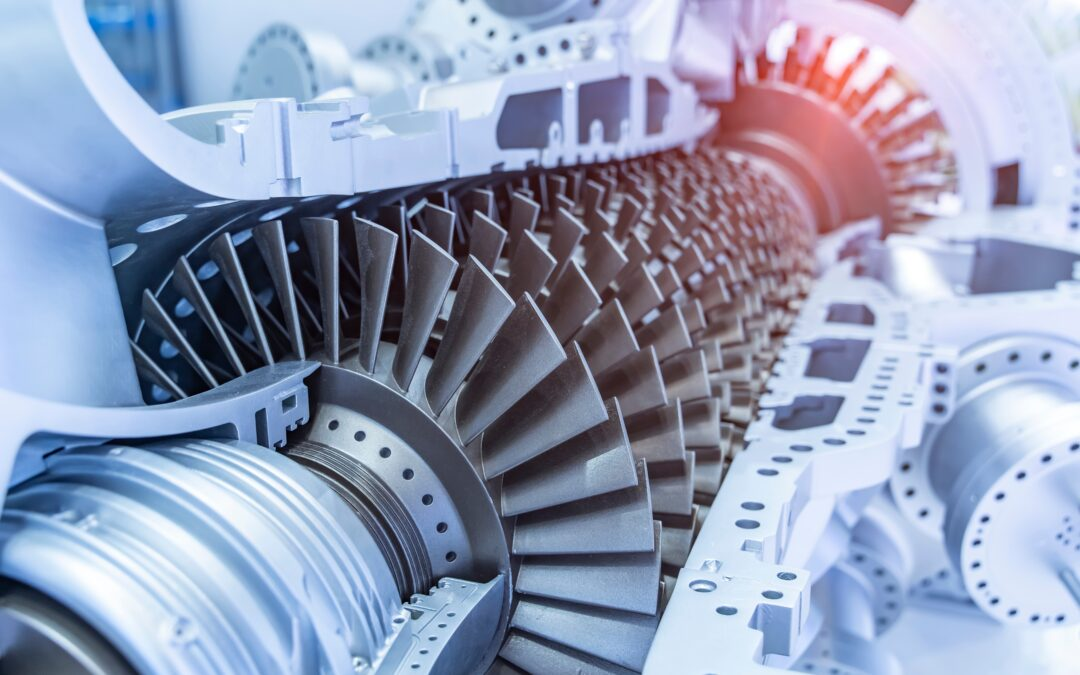

Our Core CNC Capabilities

As a certified CNC factory, we provide:

3/4/5-axis CNC milling & turning

Multi-material machining (aluminum, stainless steel, titanium, engineering plastics)

Micron-level tolerances

Rapid prototyping and low-volume production

Full inspection reports and material traceability

We’re not just ISO-certified—we’re engineering-driven and results-focused.

Clients We Serve

Industry Example Parts

Aerospace Engine mounts, brackets, housings

Medical Devices Surgical components, implant holders

Robotics Frames, arms, motor housings

Industrial Automation Precision fixtures, end effectors

Final Thoughts: Certified. Verified. Trusted.

Our ISO 9001:2015 certification isn’t just a title—it’s proof of our discipline, professionalism, and long-term commitment to our customers’ success.

When the stakes are high and the tolerances are tight, you need a machining partner who delivers more than parts—one who delivers confidence.

continue reading

Related Posts

According to product design, once you decide to use CNC to process the product, you should choose the best material, whether it is metal, plastic

According to product design, once you decide to use CNC to process the product, you should choose the best material, whether it is metal, plastic

According to product design, once you decide to use CNC to process the product, you should choose the best material, whether it is metal, plastic