get to know us

Modern industries increasingly demand components that combine macro-level structural integrity with micro- and nano-level functional features. From aerospace turbine blades with cooling micro-channels to medical implants with surface nano-texturing, success depends on multi-scale precision machining—the integration of large-scale CNC manufacturing with micro machining and nano engineering techniques.

At HTSPrecision, we specialize in bridging this gap, enabling customers to achieve performance, reliability, and innovation in their most demanding projects.

What Is Multi-Scale Precision Machining?

Multi-scale precision machining refers to the ability to manufacture parts where macro-scale geometry (5 mm–200 mm or larger) is combined with micro- and nano-scale features (1 µm–100 nm). This approach requires mastery across:

Macro Manufacturing → Structural shaping, complex geometries, and tolerance control.

Micro Machining → Features like micro-holes, grooves, and channels often smaller than a human hair.

Nano Engineering → Surface finishes and textures engineered at atomic or molecular levels to improve performance.

Engineering Challenges Across Scales

Producing components across multiple scales presents unique difficulties:

Tolerance Accumulation: Large parts with integrated micro features demand error control across different dimensions.

Thermal and Vibration Stability: Micron- and nano-level accuracy requires strict control of environmental variables.

Material Behavior: Metals like titanium, Inconel, and stainless steel react differently at macro vs. micro cutting levels.

Metrology Integration: Measurement systems must bridge scales, from CMM (Coordinate Measuring Machines) to SEM (Scanning Electron Microscopes).

Applications of Multi-Scale Precision Machining

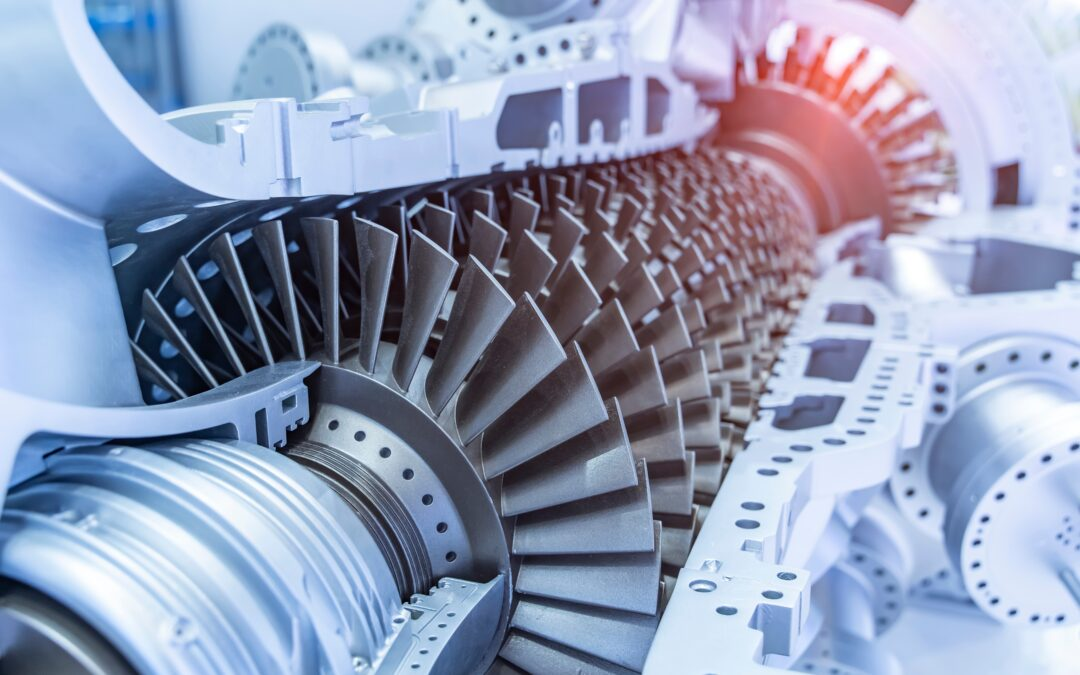

1. Aerospace & Defense

Turbine blades with cooling micro-channels.

Lightweight structures with integrated micro lattices for strength-to-weight optimization.

2. Medical & Biotechnology

Implants with nano-engineered surfaces to improve osseointegration.

Surgical tools combining macro strength with micro cutting edges.

3. Optics & Photonics

Precision housings with nano-polished reflective surfaces.

Micro lens arrays integrated into larger assemblies.

4. Semiconductors & Electronics

Heat dissipation components with micro-fin structures.

Ultra-precise housings for chip handling and wafer processing equipment.

Advanced Technologies Enabling Multi-Scale Machining

5-Axis CNC Machining: For complex macro geometry with sub-micron accuracy.

Micro-Milling & Micro-EDM: For features <50 µm.

Ultraprecision Grinding & Polishing: Achieving nanometer-level surface finishes.

Laser-Assisted Nano Structuring: Engineering surfaces with functional textures for adhesion, friction, or hydrophobicity.

Hybrid Manufacturing: Combining additive and subtractive processes for enhanced design flexibility.

Why Multi-Scale Precision Matters

Performance: Micro and nano features enhance thermal, aerodynamic, and biological interactions.

Innovation: Enables new product functionalities not achievable through single-scale manufacturing.

Reliability: Integrated precision ensures durability across operating conditions.

Global Standards: Meets the strictest requirements in ISO, AS9100, and medical-grade certifications.

The future of manufacturing lies in multi-scale precision machining—where macro structures, micro features, and nano-level engineering coexist in a single component.

By combining expertise in CNC machining, micro-fabrication, and nano engineering, HTSPrecision delivers high-performance parts that push the boundaries of design and innovation

continue reading

Related Posts

According to product design, once you decide to use CNC to process the product, you should choose the best material, whether it is metal, plastic

According to product design, once you decide to use CNC to process the product, you should choose the best material, whether it is metal, plastic

According to product design, once you decide to use CNC to process the product, you should choose the best material, whether it is metal, plastic