get to know us

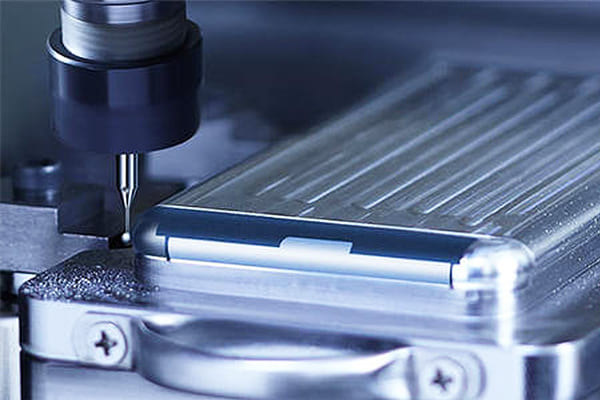

In the era of Industry 4.0, precision CNC machining is undergoing a paradigm shift. Beyond achieving micron-level tolerances, manufacturers are now focusing on real-time process monitoring—a technology-driven approach that transforms machining from a reactive process into a predictive, data-driven system.

For industries like aerospace, medical devices, semiconductors, and advanced energy systems, where quality and reliability are non-negotiable, real-time monitoring has become a cornerstone of competitive advantage.

What Is Real-Time Process Monitoring in CNC Machining?

Real-time monitoring involves embedding sensors, data acquisition systems, and analytics platforms directly into CNC machining operations. These systems track variables such as:

Cutting forces

Tool wear and spindle vibration

Thermal variations

Surface finish trends

Machine stability

By continuously collecting and analyzing this data, manufacturers can identify potential issues before they affect part quality or lead to downtime.

From Quality Control to Predictive Manufacturing

1. Data-Driven Quality Control

Traditional quality control often relies on post-machining inspection, which risks discovering errors too late. With real-time monitoring:

Defects are detected as they occur, reducing scrap and rework.

Measurement data integrates directly with CAD/CAM models, ensuring dimensional accuracy.

Statistical Process Control (SPC) methods leverage live data for continuous quality assurance.

2. Predictive Manufacturing

Predictive manufacturing goes beyond error detection—it anticipates problems:

Tool Life Prediction: Algorithms forecast when tools will wear out, preventing unexpected breakage.

Thermal Drift Compensation: Real-time thermal data feeds into machine control systems, maintaining stability.

Maintenance Scheduling: Machines notify operators of impending maintenance, reducing costly downtime.

Engineering Benefits of Real-Time Monitoring

Improved Tolerances: By compensating for vibration or heat, components meet sub-micron accuracy.

Higher Efficiency: Shorter cycle times without sacrificing quality.

Lower Costs: Reduced scrap, less unplanned downtime, and extended tool life.

Process Transparency: Engineers and clients gain full traceability for every part produced.

Applications Across Advanced Industries

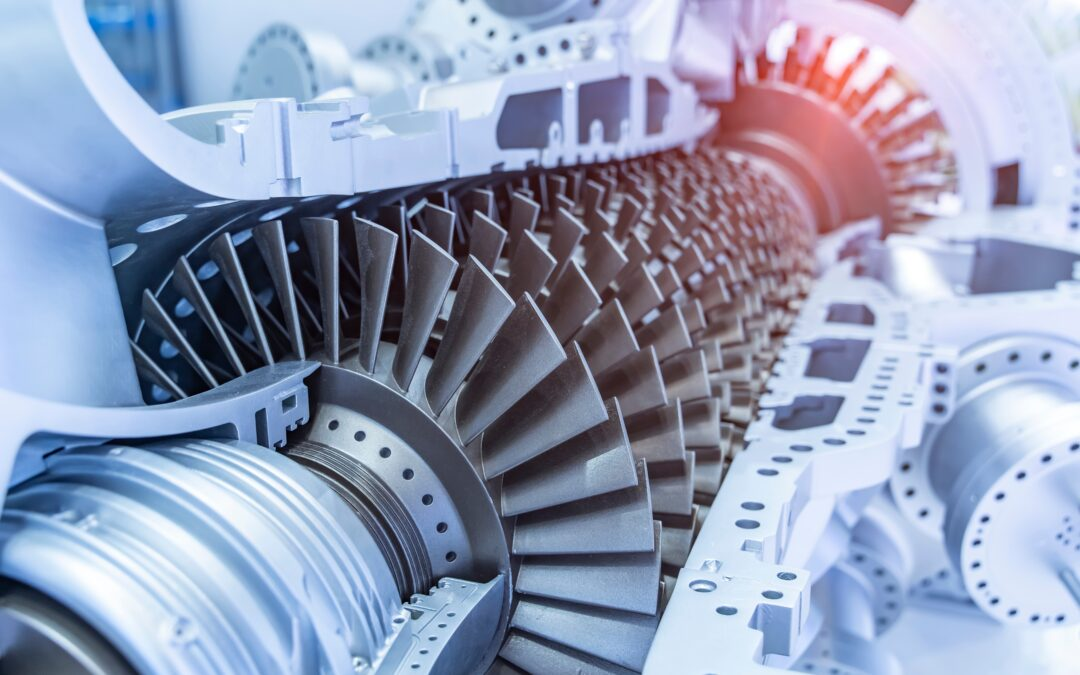

Aerospace: Ensuring flawless turbine blades and structural parts under extreme conditions.

Medical Devices: Real-time monitoring ensures implants and surgical tools meet strict biocompatibility standards.

Semiconductors: High-precision housings and wafer-handling parts demand zero error tolerance.

Energy & EV Components: Improved reliability in high-performance powertrain and battery systems.

Building Trust with Data-Backed Precision

At HTXPrecision, we integrate real-time process monitoring across our CNC machining operations. Our clients benefit from:

Complete process transparency with data-backed reporting.

ISO 9001:2015-certified quality systems enhanced with live monitoring.

Predictive manufacturing practices that ensure both speed and accuracy.

This approach allows us to deliver precision-engineered components that not only meet but consistently exceed global industry standards.

As manufacturing becomes more connected and intelligent, real-time process monitoring represents the future of precision CNC machining. By moving from reactive inspection to predictive manufacturing, companies can achieve unprecedented levels of accuracy, reliability, and efficiency.

For clients in high-demand industries, partnering with a machining provider that embraces these technologies is not just a choice—it’s a strategic advantage.

continue reading

Related Posts

According to product design, once you decide to use CNC to process the product, you should choose the best material, whether it is metal, plastic

According to product design, once you decide to use CNC to process the product, you should choose the best material, whether it is metal, plastic

According to product design, once you decide to use CNC to process the product, you should choose the best material, whether it is metal, plastic