get to know us

Explore how artificial intelligence is reshaping CNC machining — from smart automation to predictive maintenance and design optimization. Stay ahead in precision manufacturing.

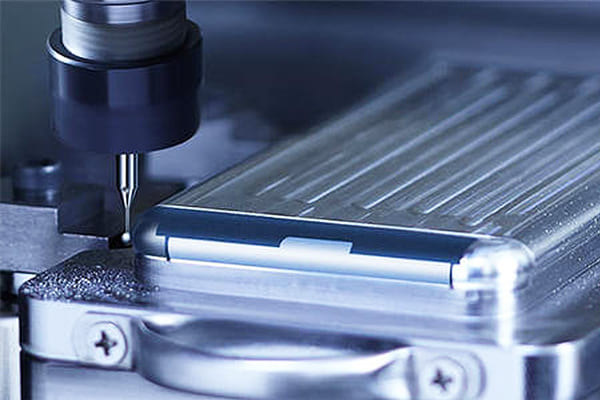

The Fusion of AI and CNC Machining

As artificial intelligence (AI) continues to transform industries worldwide, CNC machining is entering a new era of automation, adaptability, and intelligence. No longer just about cutting metal with precision, modern machining is evolving into a digitally driven, AI-powered process that offers faster production, better quality, and smarter decisions.

In this article, we explore how AI is revolutionizing the CNC industry, and what that means for custom precision machining services in the near future.

Smarter CAM Programming and Toolpath Optimization

Traditional CAM (Computer-Aided Manufacturing) relies heavily on human engineers for toolpath generation. With AI-powered algorithms, CNC machines can now:

Automatically generate optimized toolpaths based on material, part geometry, and machine capacity

Reduce cycle times by up to 30%

Improve surface finish and dimensional accuracy

Adapt in real-time to material variation or machine vibration

This means faster setup, more consistent output, and greater efficiency for complex, custom parts.

Predictive Maintenance for Maximum Uptime

Downtime is costly — especially in high-volume or precision-critical manufacturing. AI-based monitoring systems use:

Sensor data (temperature, vibration, load, etc.)

Machine learning algorithms to detect patterns

Predictive alerts before components fail

This results in minimal unplanned downtime, longer machine life, and lower maintenance costs, giving manufacturers a competitive edge.

AI-Driven Quality Control and Inspection

High-precision industries like aerospace, medical, and robotics demand zero-defect parts. AI is improving quality control by:

Enabling real-time visual inspection using cameras and deep learning

Integrating automated dimensional checks within the machining cycle

Detecting subtle anomalies that traditional methods may miss

The result? Fewer defective parts, better process consistency, and enhanced customer satisfaction.

Intelligent Quoting and Manufacturing Planning

AI also improves front-end processes:

Instant quoting systems based on historical data, part geometry, and material specs

Automated DFM (Design for Manufacturability) feedback to optimize designs before production

Dynamic scheduling of machining tasks to maximize utilization

This is crucial for custom CNC machining providers serving diverse industries with small-batch or complex orders.

Human + AI Collaboration: Not Replacement, but Enhancement

AI isn’t replacing machinists — it’s empowering them. Skilled engineers and operators remain essential, but with AI support, they can:

Focus on higher-value tasks like quality control and strategic planning

Make data-driven decisions faster

Respond more flexibly to customer needs and design changes

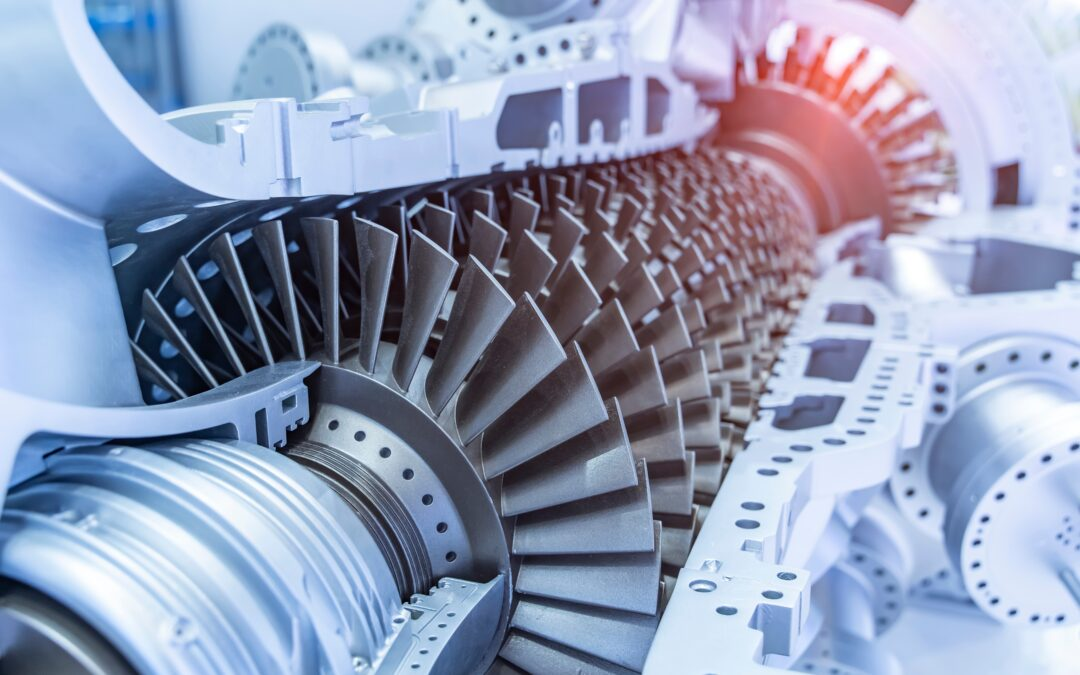

Applications in Industry: Aerospace, Medical, Robotics & More

Industries that demand high-precision custom machining are already benefiting from AI:

Industry AI-Powered Machining Impact

Aerospace Smart geometry prediction, better defect prevention

Medical Enhanced surface smoothness, tighter tolerance control

Robotics Faster prototyping, optimized part design

Automotive Real-time in-line inspection, improved tool life

In the AI age, custom CNC machining is becoming faster, smarter, and more efficient than ever before. Shops that adopt AI-powered tools — from predictive analytics to real-time optimization — will lead the way in cost-effective, high-quality manufacturing.

At HTSPrecision, we’re investing in the future with AI-enhanced workflows, ISO 9001:2015 certified quality, and a deep commitment to precision.

continue reading

Related Posts

According to product design, once you decide to use CNC to process the product, you should choose the best material, whether it is metal, plastic

According to product design, once you decide to use CNC to process the product, you should choose the best material, whether it is metal, plastic

According to product design, once you decide to use CNC to process the product, you should choose the best material, whether it is metal, plastic