get to know us

Discover our one-stop CNC machining service — from raw material sourcing to finished precision parts. Fast response, flexible customization, ISO-certified quality.

Speed, Precision, and Complete Control in Custom Manufacturing

In today’s fast-paced industrial landscape, clients demand not only precision, but also responsiveness, flexibility, and end-to-end service — from raw materials to fully inspected finished parts. At [Your Company Name], we offer a closed-loop manufacturing system designed to accelerate delivery while ensuring the highest levels of quality and customization across multiple industries.

One-Stop CNC Machining Services: From Material to Market

Our integrated production workflow provides a seamless path from raw material to finished component, enabling:

Faster lead times by eliminating outsourcing delays

Tighter quality control through in-house process monitoring

Custom solutions tailored to each customer’s industry and application

Whether you’re prototyping a new aerospace part or scaling up medical-grade production, we deliver precise, dependable, and fast results — all under one roof.

Our Closed-Loop Workflow

Here’s how our end-to-end process works:

Raw Material Sourcing

Certified materials: Aluminum, Stainless Steel, Titanium, Brass, Plastics

Material traceability and mill certificates (EN 10204 3.1)

Inventory for fast-start projects

Precision Machining

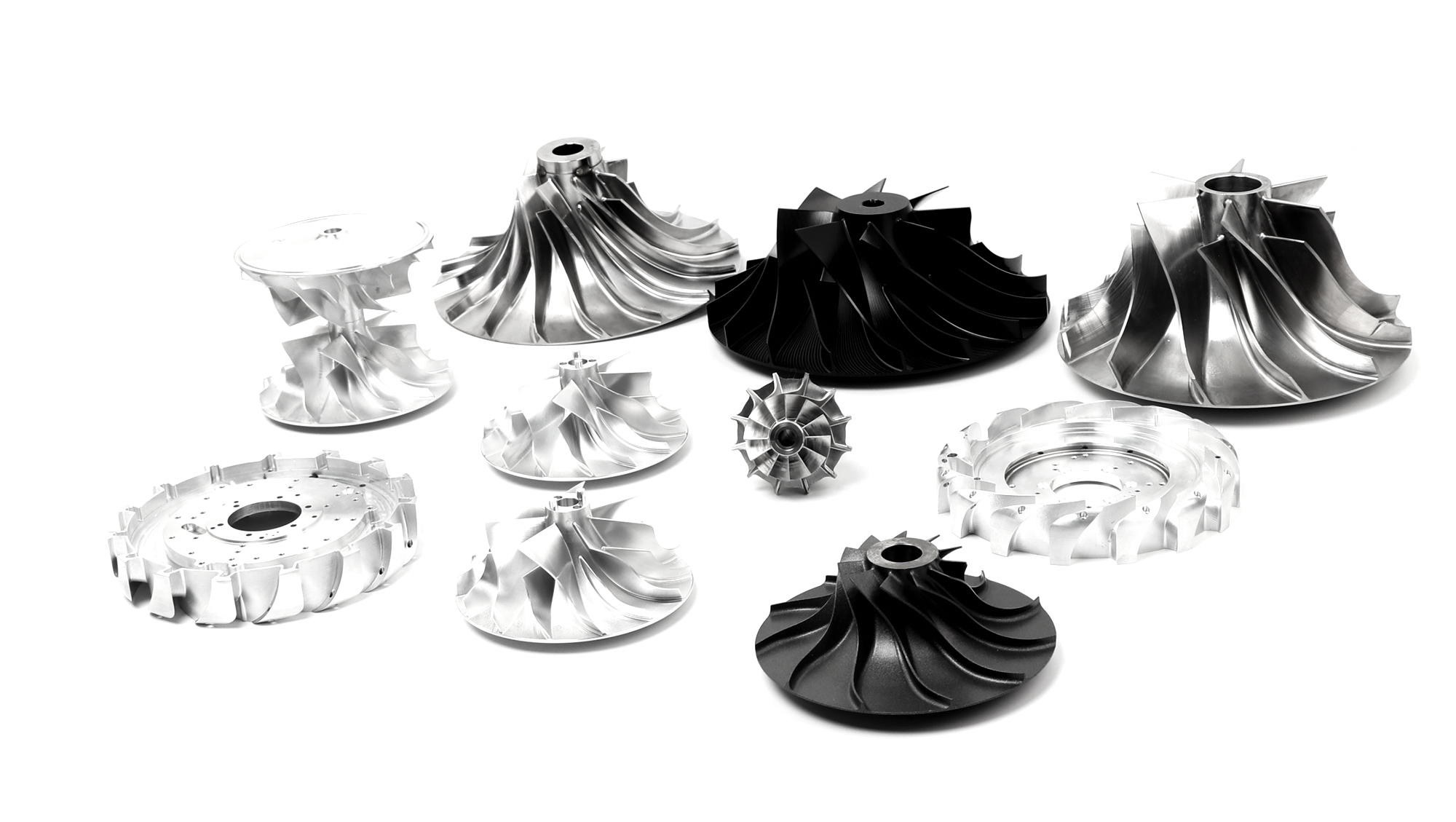

3/4/5-axis CNC milling & turning

Tolerances up to ±0.005mm

Advanced CAM programming for complex geometries

Post-Processing & Finishing

Anodizing, electroplating, bead blasting, heat treatment

Deburring and mirror polishing available

Inspection & Quality Control

CMM inspection, FAI reports, SPC data

ISO 9001:2015 certified processes

Packaging & On-Time Delivery

Global shipping (EU/US standards compliant)

Custom protective packaging per part specs

Serving Multiple Industries with Precision

Our machining services support multi-scenario demands across the following sectors:

Industry Typical Applications

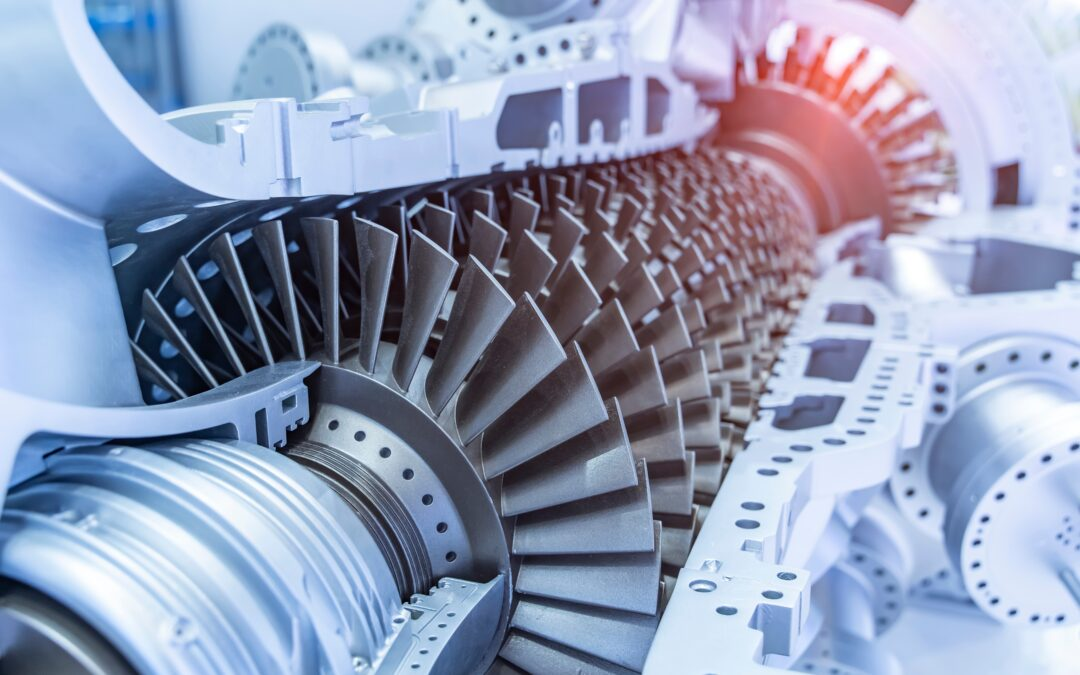

Aerospace Lightweight brackets, turbine parts

Medical Devices Implant-grade housings, surgical tools

New Energy Heat sinks, battery case components

Robotics & AI Precision gears, control arm housings

Automotive Engine parts, EV connectors

Industrial OEM Custom fixtures, mechanical enclosures

Each component we produce is application-ready and tailored to perform in its environment.

Why End-to-End Matters in Precision Manufacturing

✅ Speed: Fewer touchpoints = faster delivery

✅ Reliability: Consistent quality from start to finish

✅ Cost Efficiency: Eliminate third-party markups

✅ Flexibility: Rapid prototyping & small-batch production support

✅ Traceability: Full documentation for every production step

Clients come to us not just for parts — but for complete manufacturing confidence.

Certifications & Compliance

ISO 9001:2015 Certified Quality Management

RoHS and REACH compliant finishes

Custom PPAP, FAI, or COC documentation available on request

EU and U.S. regulatory alignment for aerospace, medical, and industrial use

continue reading

Related Posts

According to product design, once you decide to use CNC to process the product, you should choose the best material, whether it is metal, plastic

According to product design, once you decide to use CNC to process the product, you should choose the best material, whether it is metal, plastic

According to product design, once you decide to use CNC to process the product, you should choose the best material, whether it is metal, plastic