get to know us

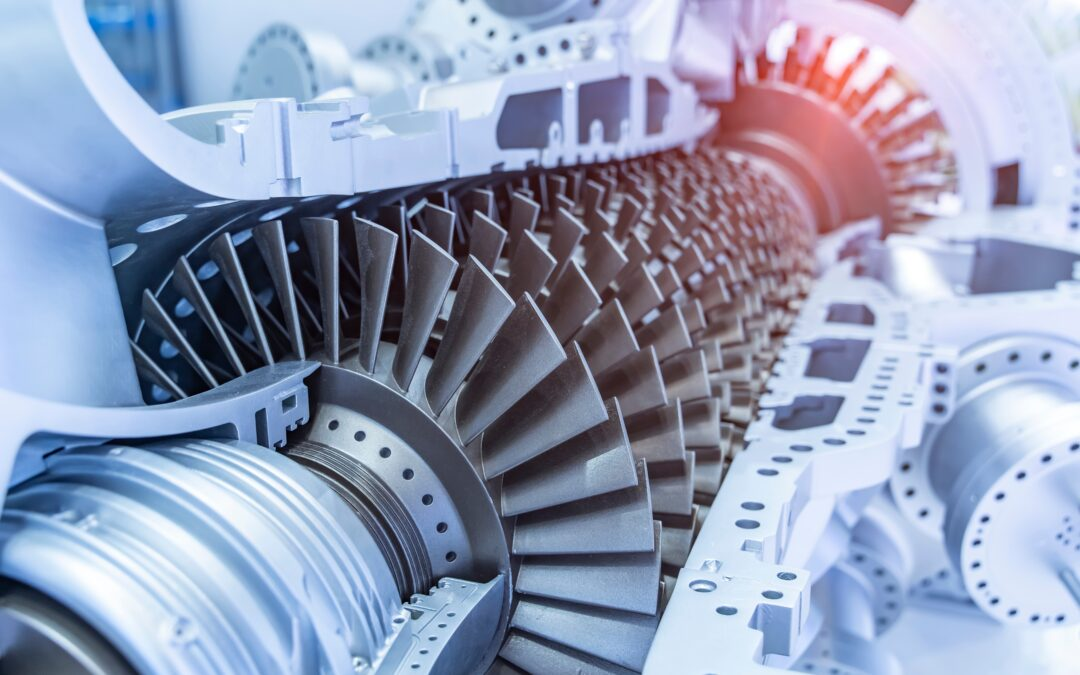

Learn how aerospace-grade metal parts are machined with ultra-high precision and what makes them essential for aircraft, satellites, and defense systems.

Introduction: The Sky Isn’t the Limit — Precision Is

The aerospace industry demands the highest levels of performance, reliability, and safety. From jet engines to spacecraft structures, every component must meet extremely tight tolerances and strict certifications. That’s where aerospace-grade metal parts machining comes into play.

This article dives into how these parts are manufactured, what materials are used, and why choosing the right machining partner is critical to success in aerospace engineering.

What Are Aerospace-Grade Metal Parts?

Aerospace-grade parts are components engineered for use in aircraft, satellites, rockets, and defense systems. These parts:

Must withstand extreme stress, temperature, and pressure

Are typically made from specialty metals and alloys

Require micron-level accuracy

Must comply with aerospace certifications like AS9100, NADCAP, or ISO 9001

Common examples include:

Engine housings

Turbine blades

Hydraulic system components

Structural brackets

Avionics enclosures

CNC Machining for Aerospace: Why It’s the Gold Standard

Computer Numerical Control (CNC) machining is the core technology behind aerospace-grade parts manufacturing. Key advantages include:

Ultra-high precision (±0.002 mm or better)

Repeatability for batch production

5-axis capability for complex geometries

Surface finishing critical for aerodynamic performance

Tight process control and traceability

From prototyping to full-scale production, CNC machining delivers the quality aerospace demands.

Quality Standards and Certifications

No aerospace part is considered complete without thorough inspection and documentation. Look for manufacturers that are:

AS9100 or ISO 9001 certified

Experienced in FAI (First Article Inspection)

Equipped for CMM and non-destructive testing

Able to supply full material traceability and documentation

Meeting these standards ensures your parts are airworthy—and audit-ready.

Applications of Aerospace-Grade Machined Parts

Commercial and military aircraft: Engine mounts, fuselage brackets, landing gear components

Space systems: Satellite housings, heat shields, propulsion parts

Defense: Guided missile components, targeting system housings

UAVs and drones: Lightweight structural components and sensor mounts

Why Choose a Specialist Aerospace Machining Provider?

Not all machine shops are created equal. For aerospace applications, the right partner should offer:

Deep understanding of material behavior under flight conditions

Proven compliance with aerospace quality standards

Ability to manage low-volume, high-precision production

Engineering support for DFM (Design for Manufacturability)

Precision That Reaches Beyond the Atmosphere

Aerospace-grade machining is a discipline where there is no room for error. From raw materials to final inspection, every step must meet the highest industry standards. Whether you’re working on the next-generation jet or a Mars-bound satellite, precision machining is your launchpad to success.

continue reading

Related Posts

According to product design, once you decide to use CNC to process the product, you should choose the best material, whether it is metal, plastic

According to product design, once you decide to use CNC to process the product, you should choose the best material, whether it is metal, plastic

According to product design, once you decide to use CNC to process the product, you should choose the best material, whether it is metal, plastic