get to know us

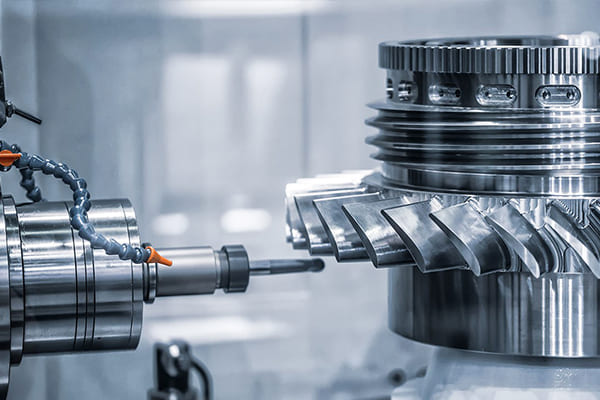

In high-precision manufacturing, maintaining micron-level accuracy isn’t just about advanced machinery or tight tolerances — it’s about mastering thermal stability. Even a temperature fluctuation of a few degrees can cause micro-expansion in metals, shifting tool paths and compromising dimensional integrity.

For industries like aerospace, semiconductor, energy systems, and medical devices, where a 5 µm deviation can mean performance failure, controlling thermal effects is critical. In this article, we’ll explore how advanced CNC facilities achieve thermal stability and why it defines the next level of precision machining excellence.

Why Thermal Stability Matters in Precision Machining

Every machining process generates heat — from tool friction, spindle rotation, or environmental conditions. When this heat is not properly managed, it leads to:

Thermal expansion of materials, distorting dimensions

Tool deflection under prolonged heat stress

Inconsistent surface finishes

Misalignment in multi-axis operations

For instance, a 100 mm titanium part can expand by more than 2 µm with only a 1°C temperature increase. In aerospace components or optical assemblies, that’s the difference between perfect alignment and catastrophic misfit.

Material Science Behind Thermal Behavior

Different materials respond to temperature in distinct ways.

Material Thermal Expansion Coefficient (µm/m·°C) Key Consideration in Machining

Aluminum 23 Rapid expansion; needs strict thermal compensation

Steel 12 Stable under moderate heat; benefits from cooling

Titanium 8.5 Excellent thermal resistance but poor heat dissipation

PEEK 47 Highly sensitive to temperature; requires low-heat tooling

Precision machining experts must choose not only the right material, but also adapt their cutting parameters, coolant systems, and tool paths according to thermal characteristics.

Engineering Solutions for Thermal Stability

Modern CNC workshops use a combination of engineering controls and intelligent compensation systems to achieve consistent accuracy:

(1) Temperature-Controlled Environments

Machining centers are often placed in climate-controlled facilities (±0.5°C) to minimize ambient fluctuations. For ultra-precision work, entire production lines operate in cleanrooms to stabilize humidity and air density.

(2) Thermal Compensation Software

Advanced AI-driven CNC controllers now predict and correct for thermal deformation in real time. These systems use temperature sensors on spindles, workpieces, and tool holders to calculate expansion coefficients and auto-adjust cutting positions.

(3) Coolant and Lubrication Systems

High-performance coolant circulation removes excess heat, while minimum quantity lubrication (MQL) ensures efficient thermal balance with minimal environmental impact.

(4) Machine Structure Design

State-of-the-art machines feature symmetrical frames, granite or polymer bases, and air-bearing spindles — all designed to reduce heat transfer and vibration.

Application Examples

Aerospace Turbine Components: Maintaining sub-micron tolerance during high-speed machining of nickel alloys under high thermal stress.

Semiconductor Molds: Precision cavity machining in temperature-sensitive environments to ensure dimensional repeatability.

Medical Device Manufacturing: Controlling heat buildup when machining PEEK and titanium implants for biocompatibility and accuracy.

Optics and Photonics: Ultra-stable machining for aluminum lens mounts where temperature-induced distortion must be near zero.

The Future: Smart Thermal Compensation

Next-generation Industry 4.0 manufacturing integrates machine learning and digital twins to predict temperature behavior even before production starts. These systems simulate thermal responses, optimize toolpath strategy, and implement closed-loop feedback to maintain true micron-level consistency throughout multi-hour machining cycles.

Thermal stability is the silent foundation of precision machining excellence. While surface accuracy and geometric control get the spotlight, it’s thermal control that ensures repeatability, quality, and longevity of performance.

At HTS Precision, we combine advanced thermal compensation, temperature-controlled environments, and intelligent CNC systems to guarantee ultra-precise machining results for global clients. Whether working with titanium, aluminum, or engineering plastics, we ensure your parts perform flawlessly — even under extreme conditions.

continue reading

Related Posts

According to product design, once you decide to use CNC to process the product, you should choose the best material, whether it is metal, plastic

According to product design, once you decide to use CNC to process the product, you should choose the best material, whether it is metal, plastic

According to product design, once you decide to use CNC to process the product, you should choose the best material, whether it is metal, plastic