500+

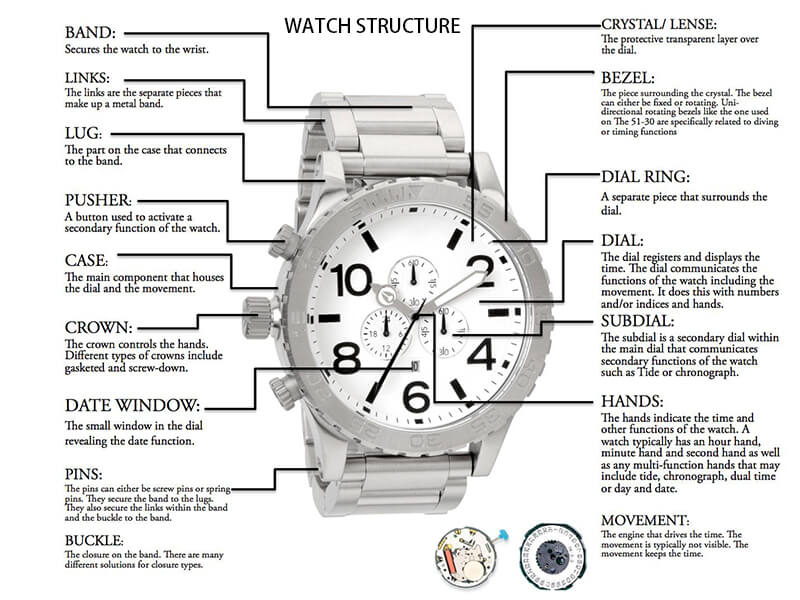

Watch Parts CNC Machines

350+

Dipendente

professional Watch Parts Maker, Supplier, Manufacturer

With more than 20 years of industry experience and a state-of-the-art dedicated watch manufacturing facility covering an area of 5000 square meters, Htsin Precision has the experience, talent and vision to provide quality OEM watch parts customization and commercial mass manufacturing. Our flexible design process and extensive manufacturing scope mean we can quickly create unique designs, moving from idea to production while meeting the most demanding lead times.

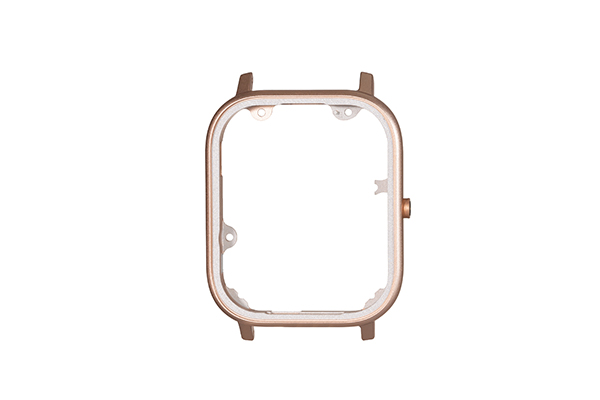

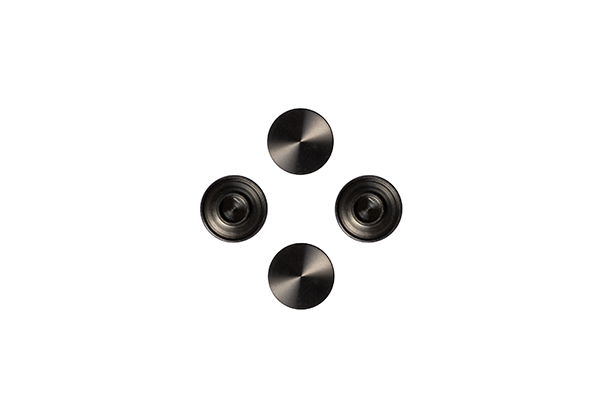

We have cooperated with watch brands such as Apple, Xiaomi and Huawei for many years, and participated in the design and mass production of more than 20 kinds of parts such as watch case, buckle, crown, bezel, button, etc., with a total of more than 200,000 parts. Work with Htsin Precision for custom watch parts to customer design specifications (OEM). We ensure your OEM and ODM needs are met effectively through a well-designed process.

Brands We Work With

We are Focus on

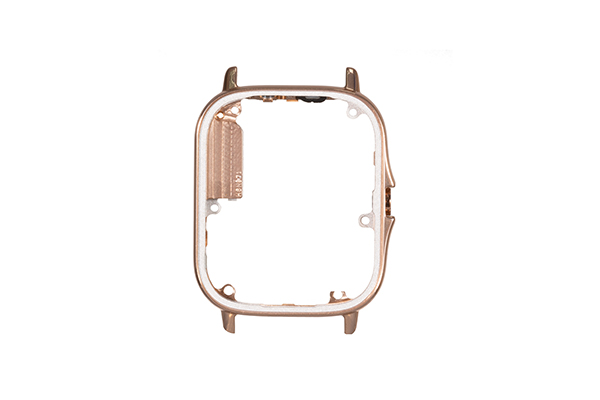

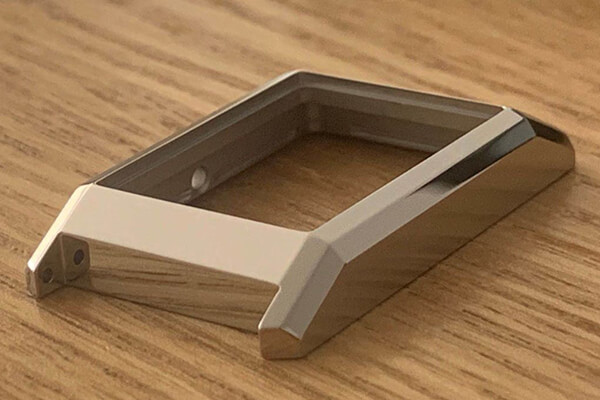

Watch Case Manufacturing

Htsin Precision is well-known as the best watch case manufacturer, manufacturer, supplier in China.

Watch Buckle Manufacturing

Looking for manufacturers of metal watch bands, buckles. Find out how Htsin can help you.

Why Choose Us ?

Latest Cases

HTSIN è un fornitore di lavorazioni batch di parti CNC per quasi tutti i settori. Questo perché i nostri servizi di lavorazione possono gestire tutti i materiali possibili e parti complesse. I materiali richiesti possono includere alluminio, acciaio, ferro, bronzo, zinco, le loro leghe e quasi tutti i metalli disponibili. Utilizzato in elettronica, comunicazioni, giocattoli, produzione di attrezzature e altri campi

Needs Exploration & Design

The OEM & ODM starts with the analysis of your needs. If you are thinking of designing a watch, our innovative design team will have an in-depth conversation with you to discuss your idea, your requirements and your budget. Even if you just have a rough idea in your head, each member of our team has unparalleled experience in OEM watch design, which includes both OEM women’s watch and OEM men watch, and will guide you through the process. They will be able to provide you with popular design trends to get inspiration for the creation of your customized watch.

A great design is the key to great product. After the creation of the idea, our team of experts will use computer-aided software to come up with 2D and 3D images of your OEM&ODM watch design, so that you are able to view the final product from all angles.

Rapid watch prototyping and efficient series manufacturing

Rapid watch prototyping and efficient series manufacturing

As a professional OEM and ODM original watch design manufacturer, Htsin has a professional team of watch experts to take designs from sketches to production stage. End-to-end manufacturing of complete watch OEM production lines. From design to packaging, we take care of every step of the production process, delivering quality products to your specifications using our custom cutting-edge manufacturing facilities.

Strict adherence to quality control at all levels of the manufacturing process facilitates the production of fully custom OEM watches to your specifications. As one of the well-established OEM watch suppliers in China, we will ensure that your needs are met and the best quality products are delivered promptly according to your order size and timing.

pianificazione fiscale

Eiusmod tempor incididunt ipsum ut labore dolore magna aliqua. Ut enim minim veniam duisy ipsum sed quis.

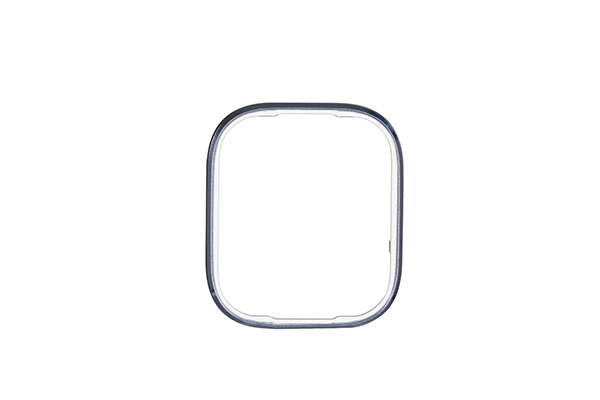

Inspection & Packaging

Before shipment, we will do strict product inspection and testing, including air tightness test, appearance defect inspection, dimensional accuracy measurement, surface roughness inspection, etc., to ensure that the products shipped out of the factory meet the quality standards.

Product packaging plays an important role in any product. Our team of watch OEM experts can discuss packaging options based on your brand identity, watch style and target market. They will help you choose the appropriate packaging design and customize your OEM watch to meet your needs.

Our Capability

Il nostro magazzino dispone di scorte sufficienti di materie prime comuni, i modelli in metallo e plastica comunemente usati sono:

| Metallo | Plastica |

| Alluminio | Acrilico |

| Ottone | PTFE |

| Rame | HDPE |

| Bronzo | Teflon |

| Acciaio | PC (policarbonato) |

| Acciaio inossidabile | PVC |

| Titanio | PP (polipropilene) |

| Zinco | Plastica ABS |

| Nylon |

Le tolleranze sui metalli saranno mantenute a +/- 0,005″ (+/- 0,127 mm) in conformità con ISO 2768 se non diversamente specificato. Materie plastiche e compositi saranno +/- 0,010”.

| Intervallo dimensionale (mm) | Bene (FA) | Medio (M) | grossolano (C) | Molto grossa (V) +/- |

| +/- | +/- | +/- | ||

| 0.5-3 | 0.05 | 0.1 | 0.2 | — |

| 3-6 | 0.05 | 0.1 | 0.3 | 0.5 |

| 6-30 | 0.1 | 0.2 | 0.5 | 1 |

| 30-120 | 0.15 | 0.3 | 0.8 | 1.5 |

| 120-400 | 0.2 | 0.5 | 1.2 | 2.5 |

| 400-600 | 0.3 | 0.8 | 2 | 4 |

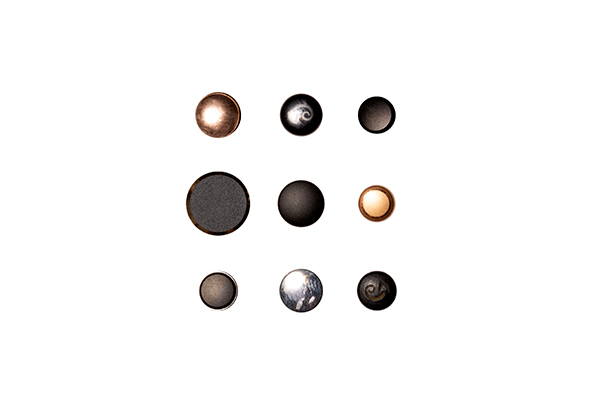

In Htsin Precision, crediamo che la differenza tra un bell'orologio e un grande orologio sia l'attenzione ai dettagli, la finitura delle parti e, soprattutto, la cassa. Offriamo diverse finiture di orologi per dare alle tue creazioni lo splendore che meritano.

Oltre ai nostri metodi di lucidatura estremamente precisi che producono risultati brillanti, offriamo anche pallinatura ultra fine, incisione chimica, stampaggio e PVD per far brillare ogni dettaglio.

Possiamo eseguire il trattamento superficiale in base alle esigenze del cliente, i metodi di lavorazione sono i seguenti:

- Anodizzato

- Lucidatura

- Placcatura al nichel

- Zincatura

- Spazzolatura

- Incisione laser

- Nero ossido

- Trattamento termico

- Sabbiatura

- Elettroforesi ecc.

Oltre la precisione di Htsin

Steps of Watch Mod Parts Manufacturing in Htsin

In ogni fase, orologiai esperti e ben addestrati aggiungeranno anni di maestria artigianale, non solo viti, parti e ingranaggi, con ogni gesto preciso e mirato.

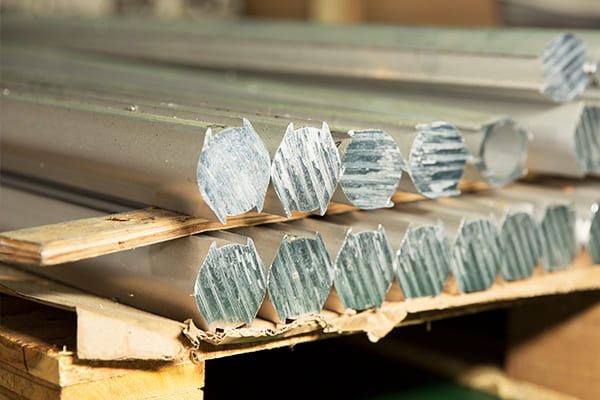

1, materiale

Siamo in grado di lavorare la maggior parte dei materiali metallici e plastici

Conferma materiale, ispezione materiale IQC

Deposito materiale

Ispezione e taglio della billetta

1 Acquista materiale in alluminio su richiesta

2 Ispezione IQC per il materiale

3 Materiali controllati Entrare nel magazzino

4 billetta per orologio da taglio a macchina per sega

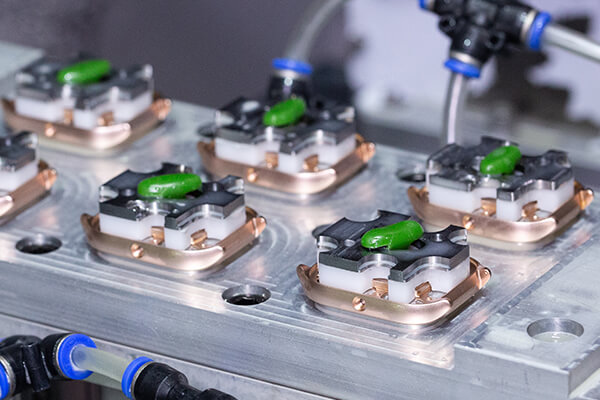

2, lavorazione CNC

Tornitura CNC, Fresatura CNC, Lavorazione CNC SWISS, Lavorazione CNC a 3,4,5 assi, Graving CNC ecc.

Lavorazione CNC di parti di orologi

Cassa dell'orologio di fresatura CNC

Parti di orologi CNC e ispezione

1 parti di orologio lavorate a CNC 3 volte

2 fori di posizionamento per fresatura CNC

3 Ispezione di controllo del processo IQC

3, trattamento superficiale

Anodizzato, Lucidatura, Nichelatura, Zincatura, Spazzolatura, Incisione laser, Ossido nero, Trattamento termico, Sabbiatura, Elettroforesi, ecc.

Lucidatura della superficie della cassa dell'orologio

Trattamento polacco prima dell'ossidazione dell'anodo

Finitura superficiale

1 Lucidatura manuale

2 Test di dimensione IQC

3 fori laterali di lavorazione CNC, rettifica delle sbavature

4 Pulizia e asciugatura

5 Spruzzo di sabbia, biossido di anodo

6 Controllo FQC

7 Pulizia ad ultrasuoni

4, finalmente test e imballaggio

Prodotto in stretta conformità con il processo di controllo della qualità, garanzia della qualità.

Controlla il difetto

Ispezione finale

Finalmente Ispezione e Imballaggio

1 Controllare la tenuta del gas

2 Un difetto di ispezione della lente d'ingrandimento

3 Ispezione completa del gruppo

4 Controllo finale OQC

5 Imballaggio prima della consegna

cliente

testimonianze

Altissima qualità, consegna puntuale e servizi professionali. Altamente raccomandato 👍

Edoardo Kinsjer

Tutto inizia con una consulenza!

Guarda la produzione di parti su richiesta

Per qualsiasi tipo di domanda, inviare un'e-mail

No. 5, Xingfa Road, Junzibu Community, Guanlan Town, distretto di Longhua, Shenzhen, Cina 518100